AERO ENGINEERING & MANUFACTURING

Products & Capabilities

Aero Engineering & Manufacturing has the equipment and engineering capabilities needed to support 21st century requirements for legacy products.

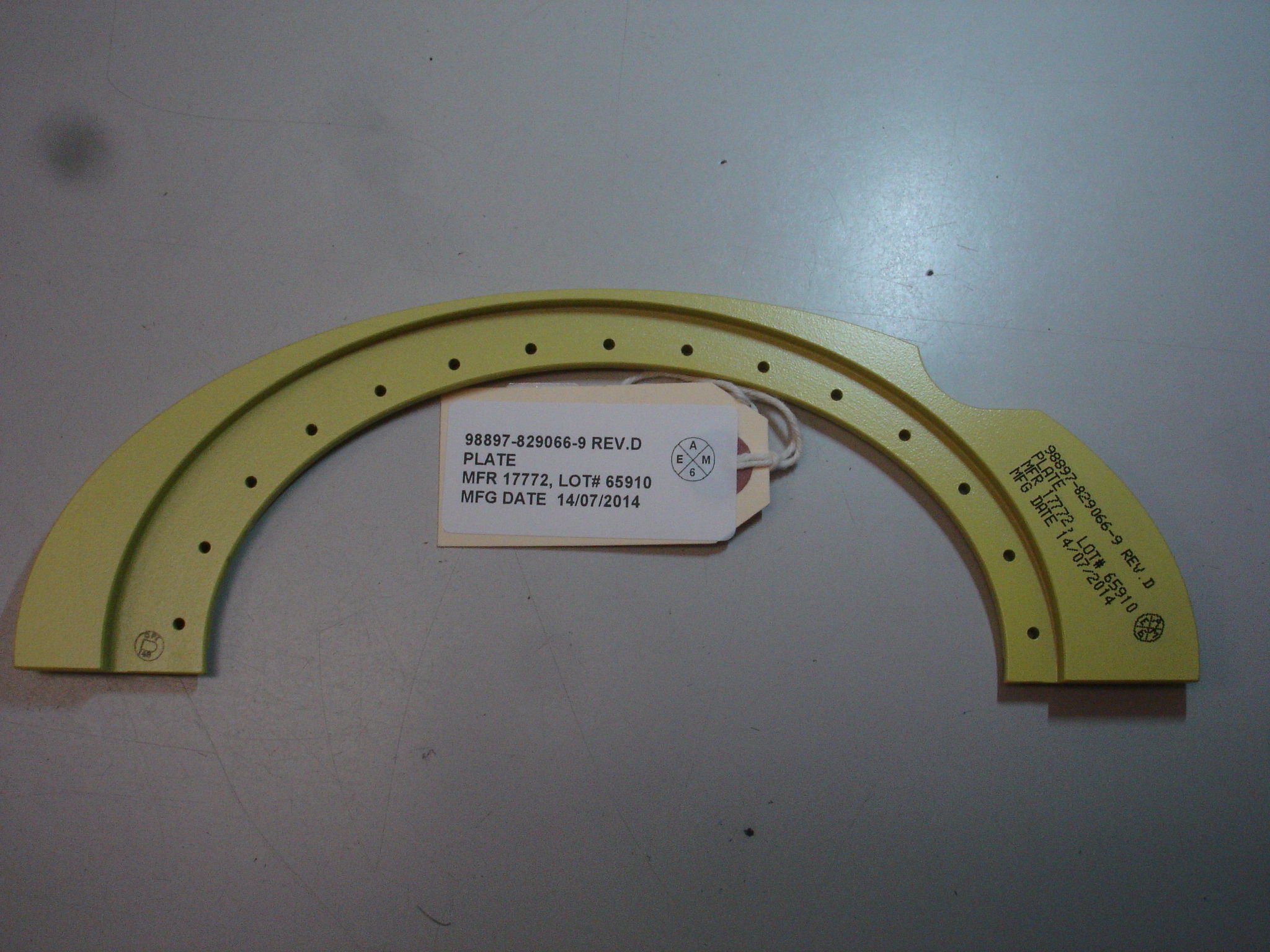

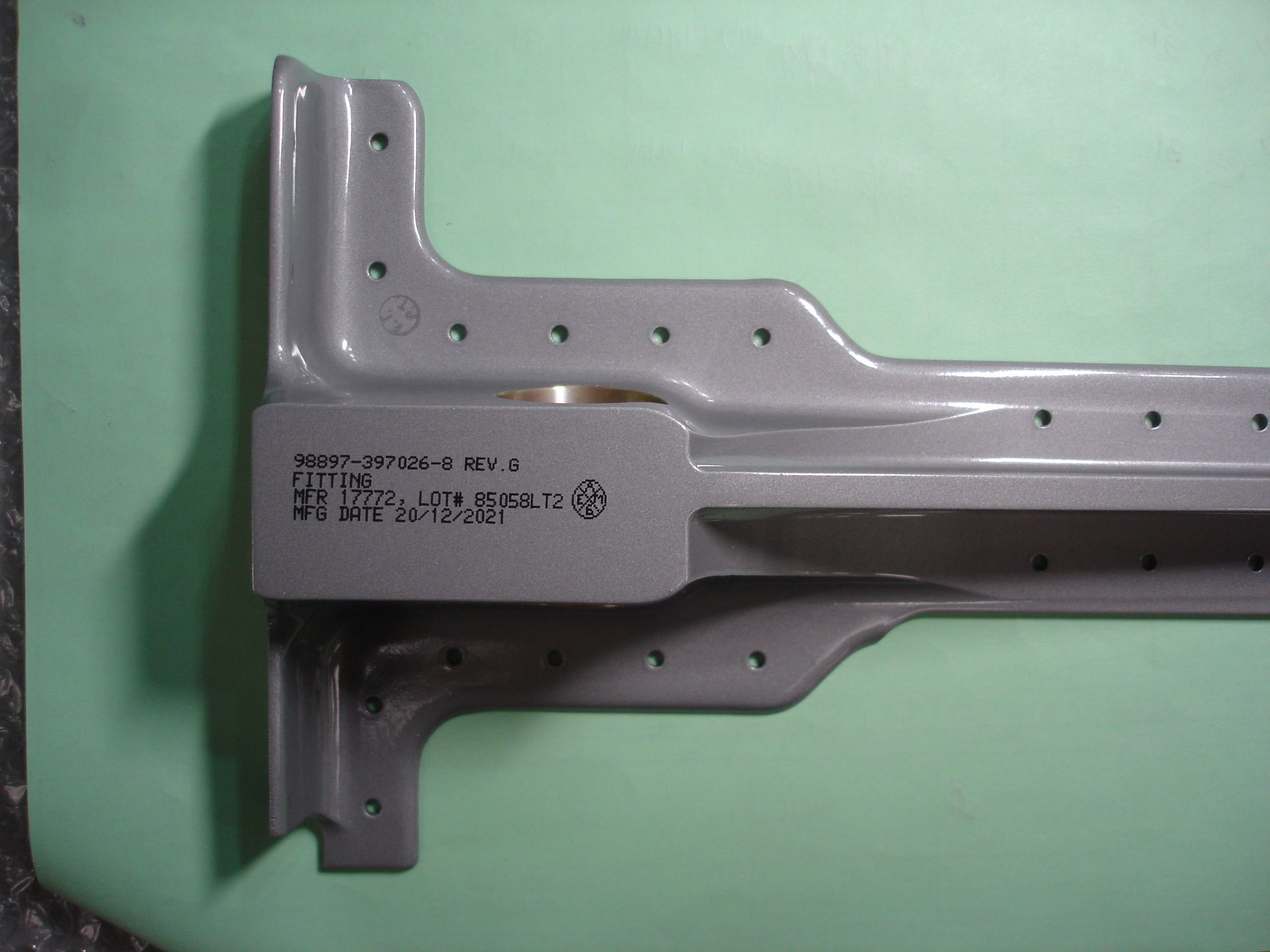

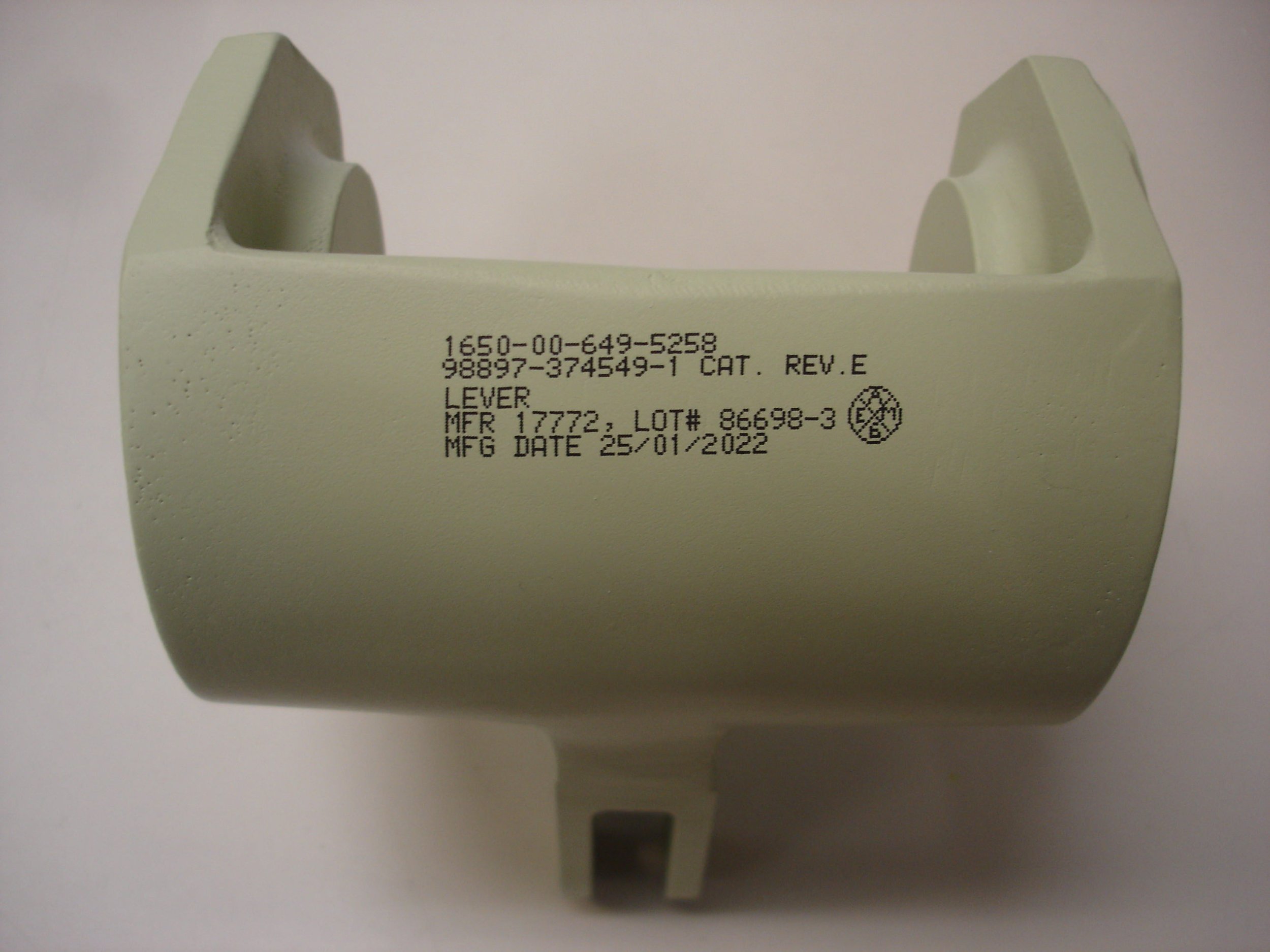

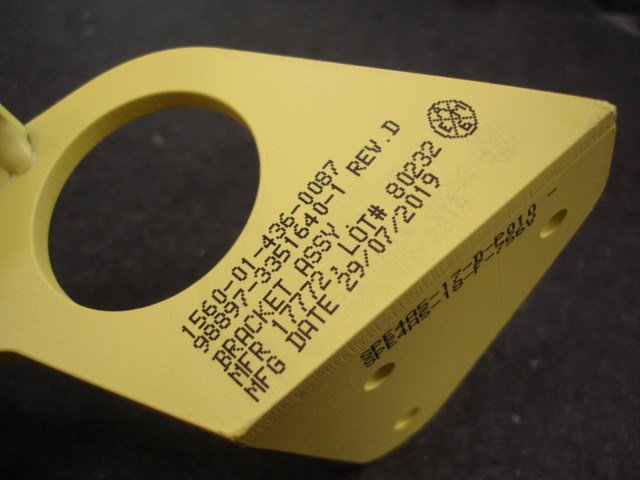

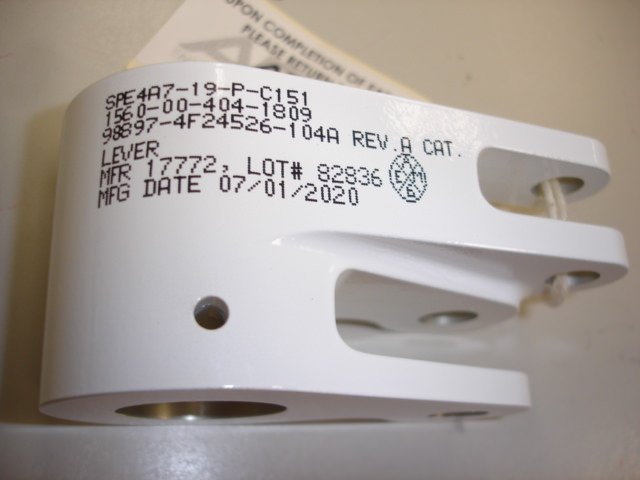

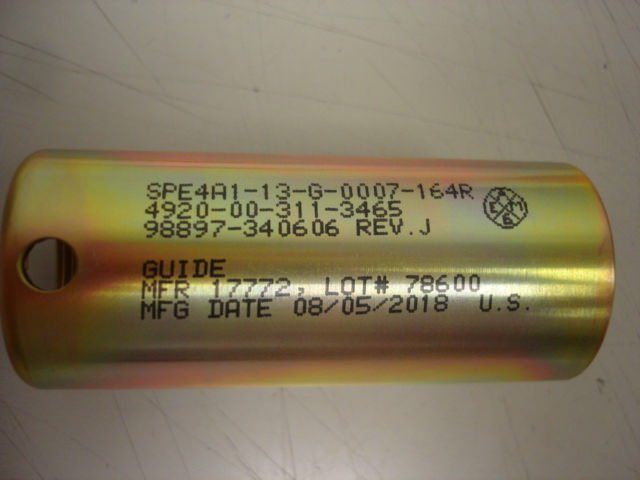

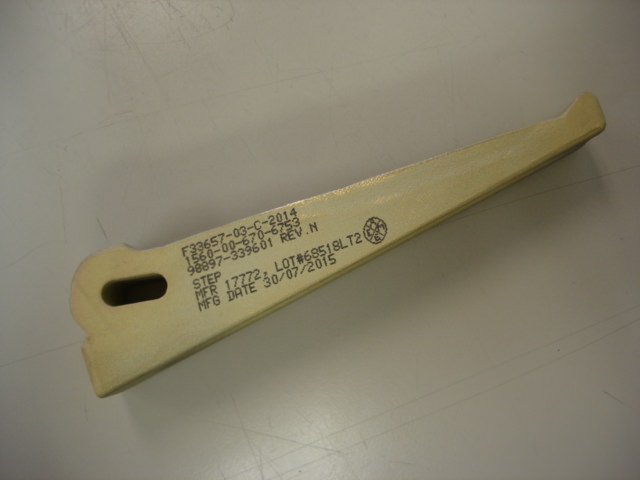

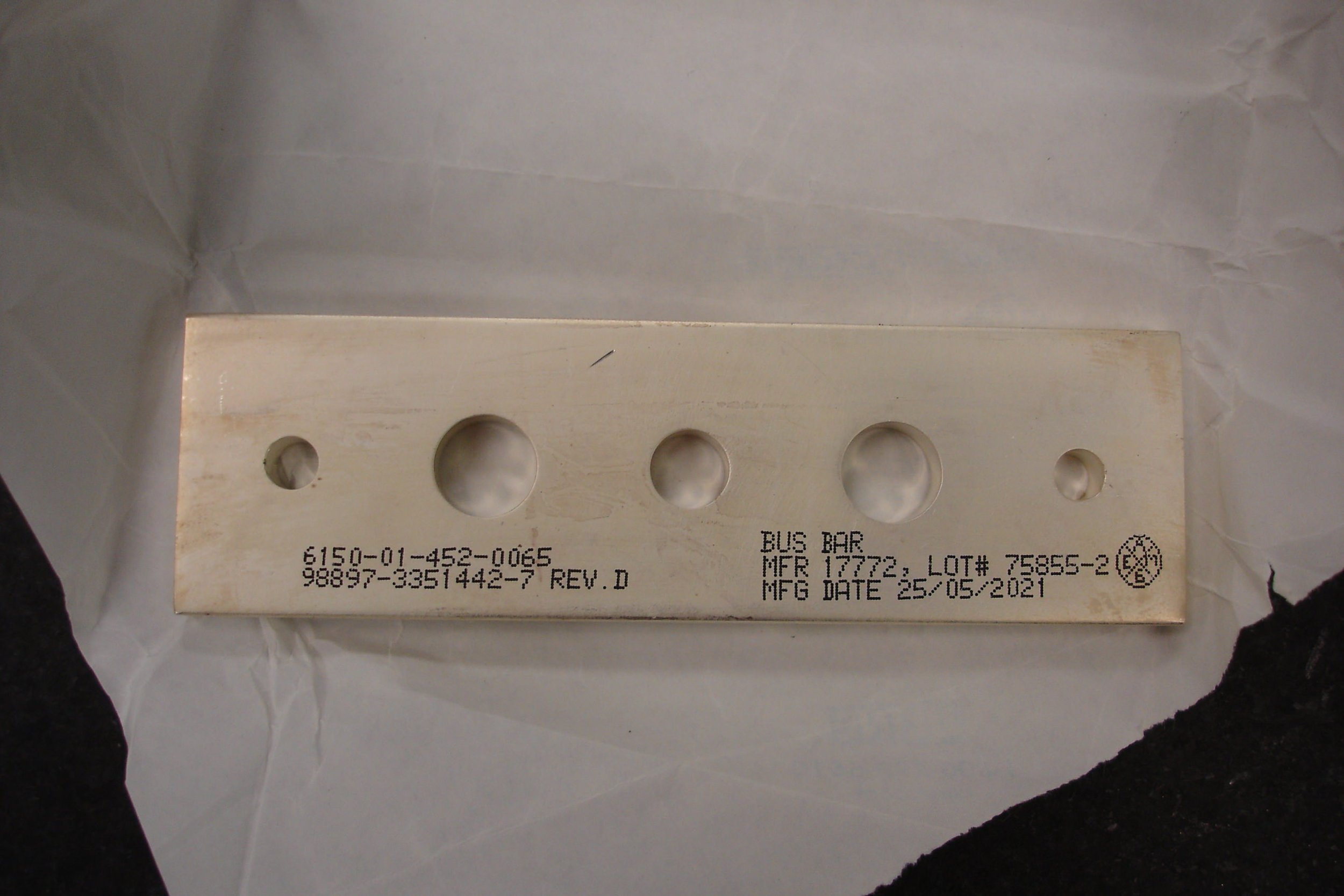

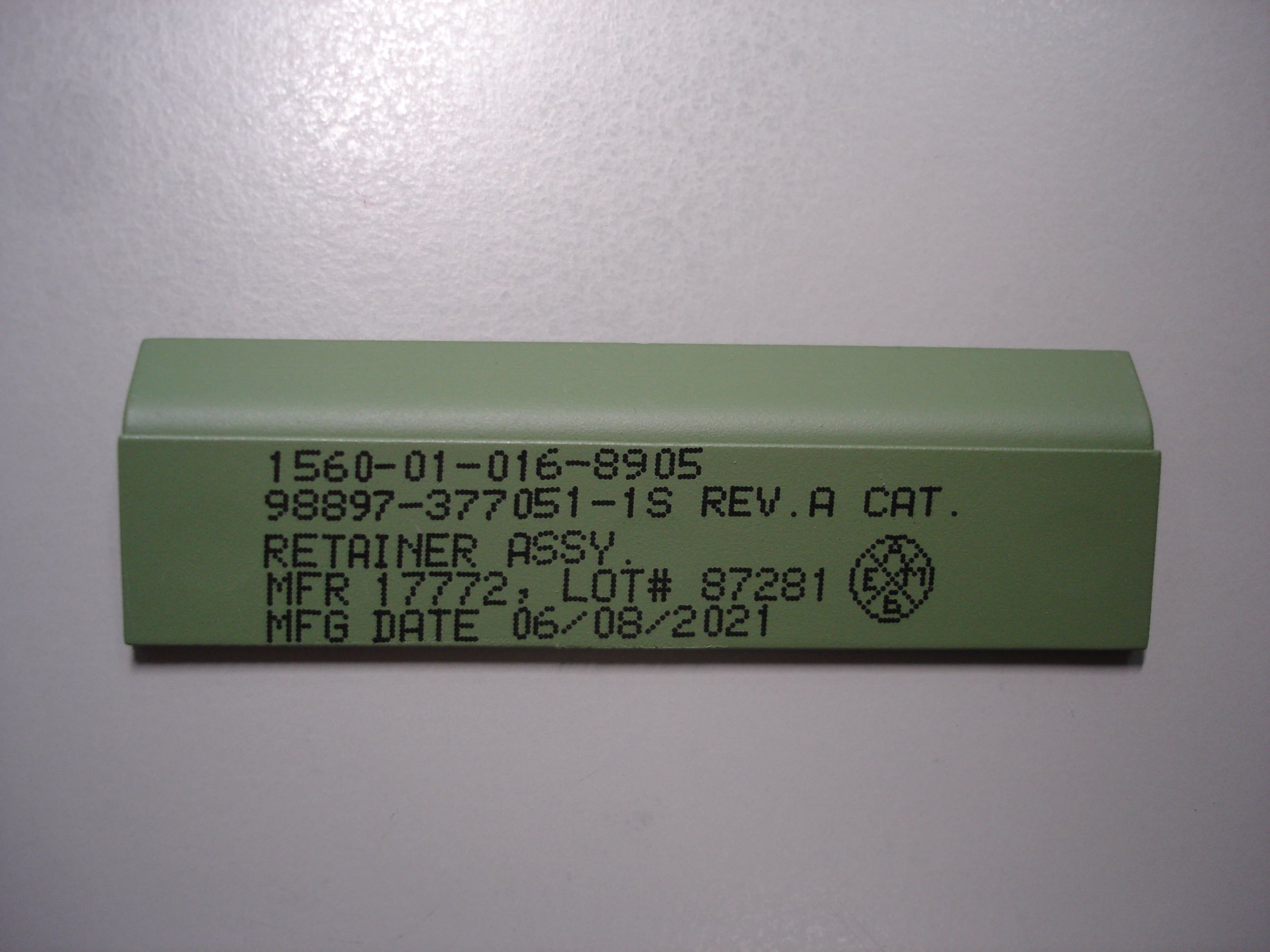

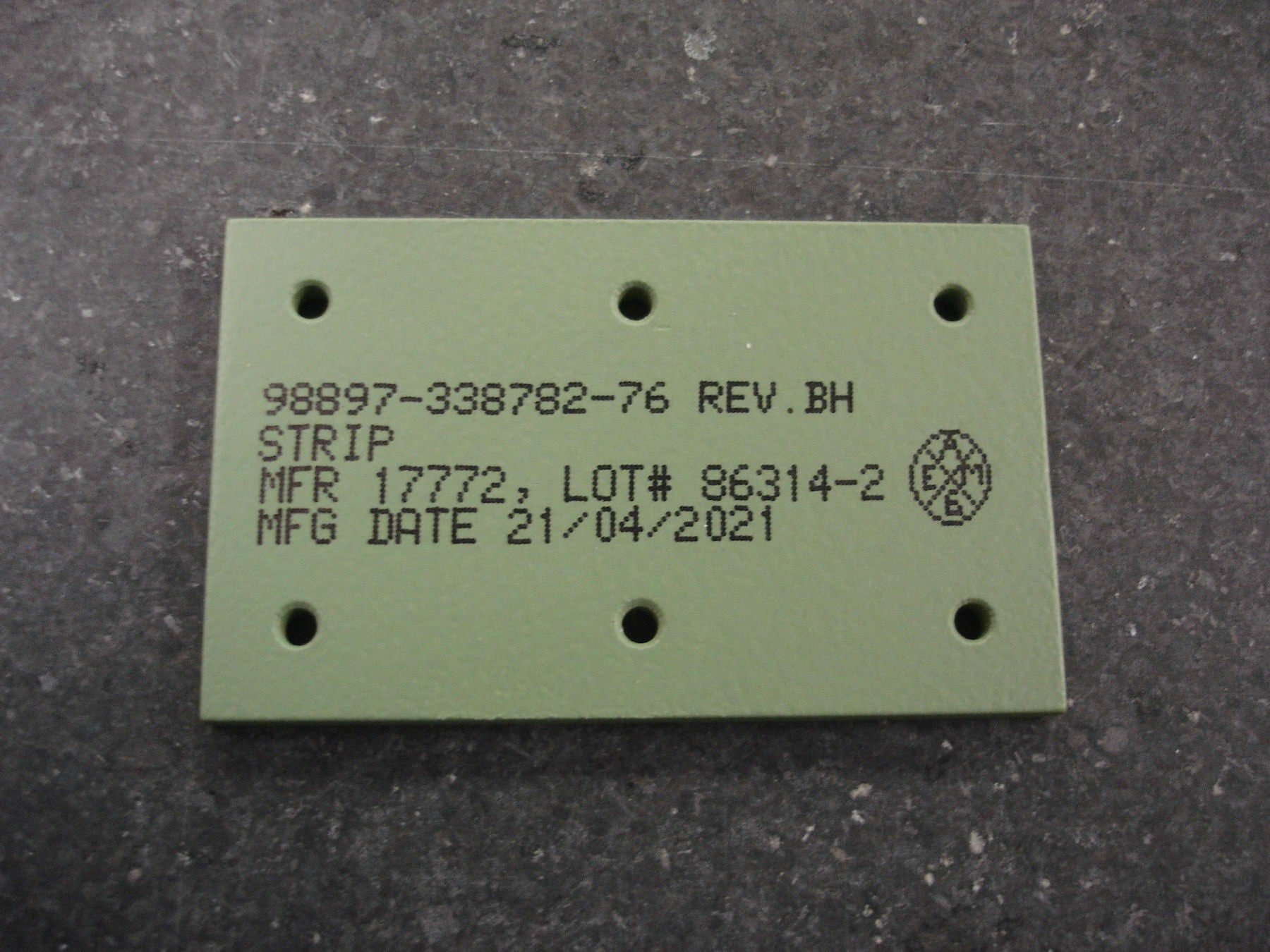

Aero utilizes customer inputs ranging from the latest Model Based Definition data packages to original hand drawings required to support current and legacy platforms. Our Engineering, Manufacturing, and Quality team utilizes the latest CAD/CAM and 3D modeling tools, CNC controlled equipment, Inspection tools and controlled processes to meet the complex requirements of our customers.

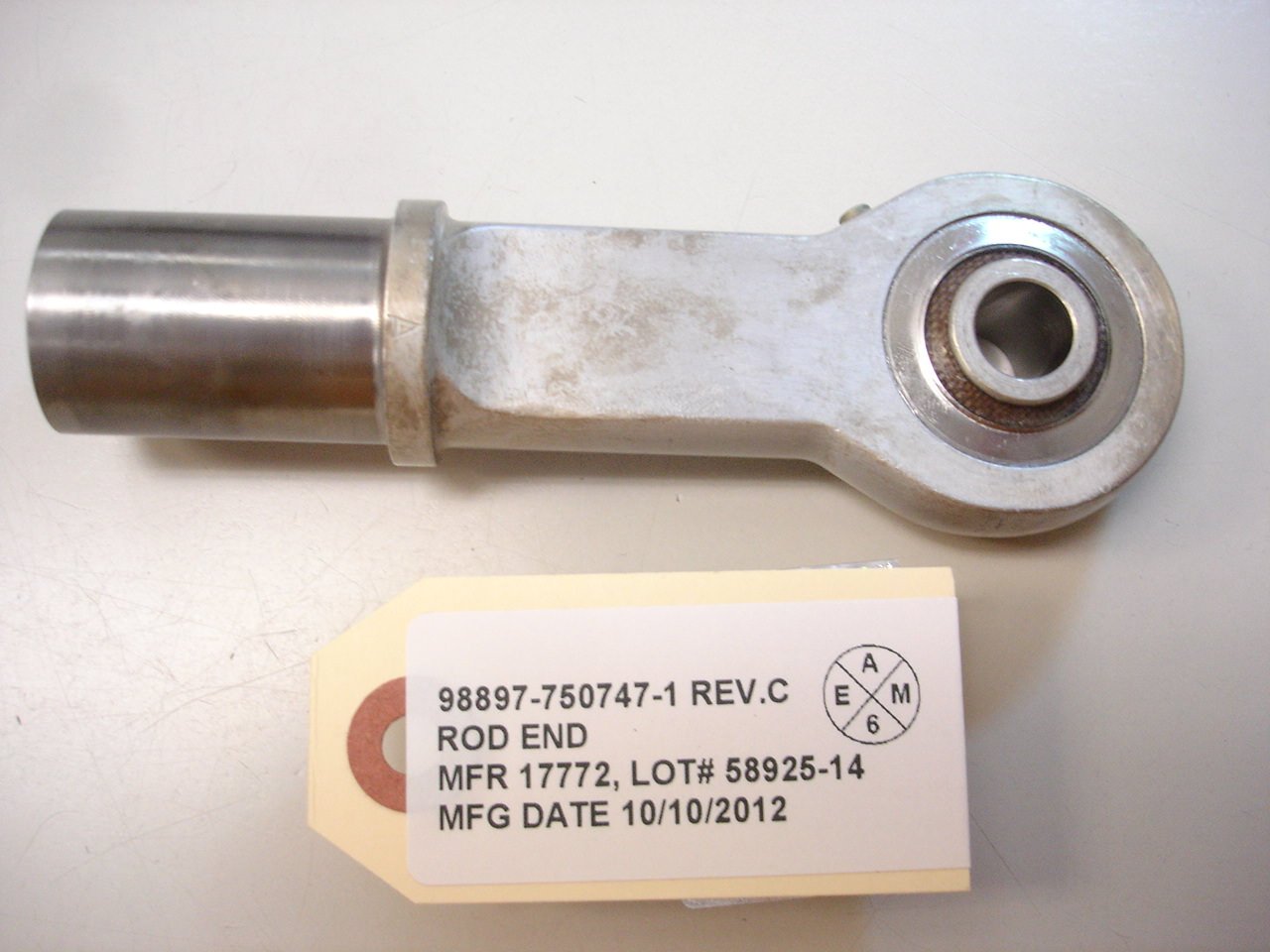

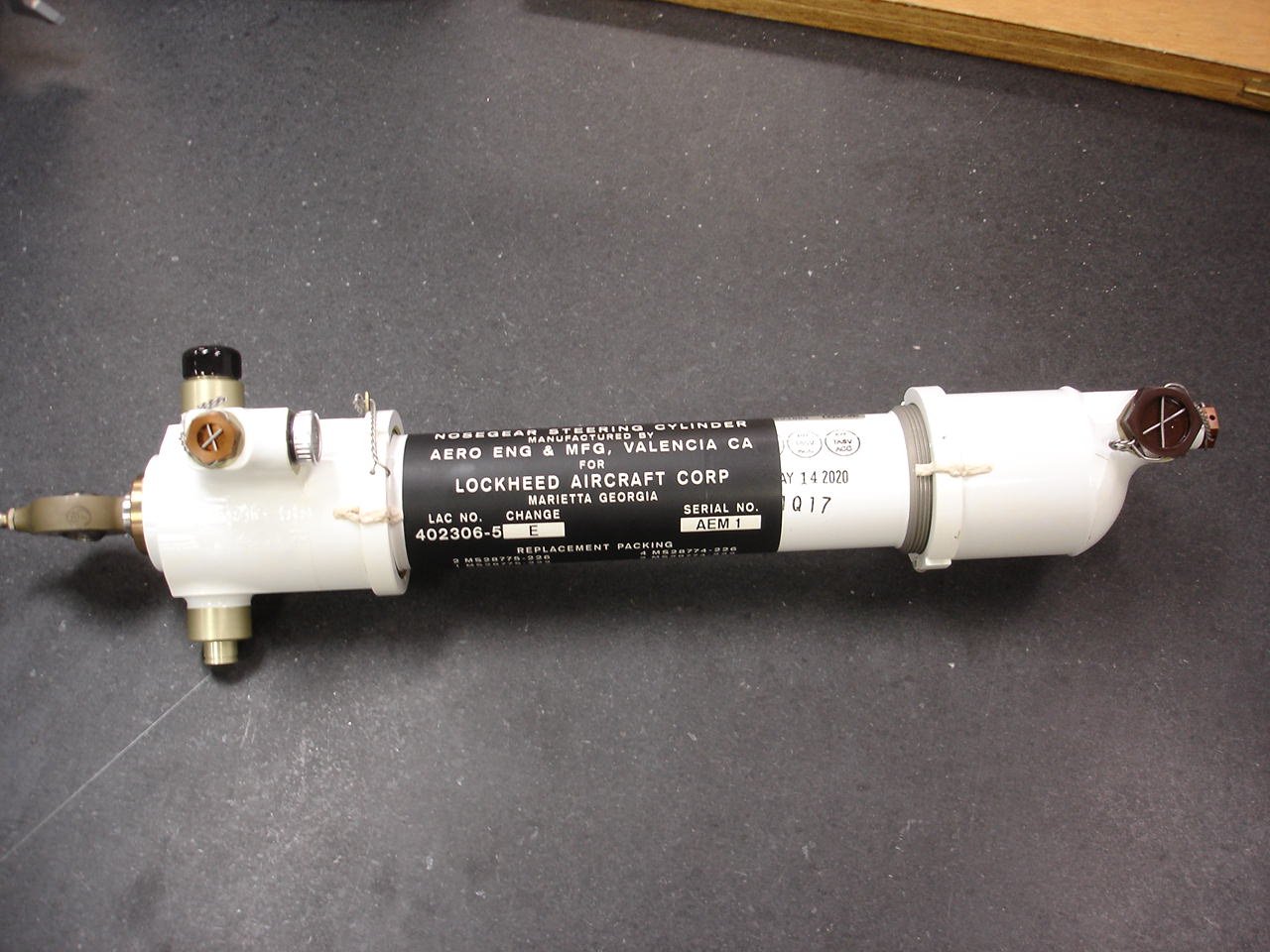

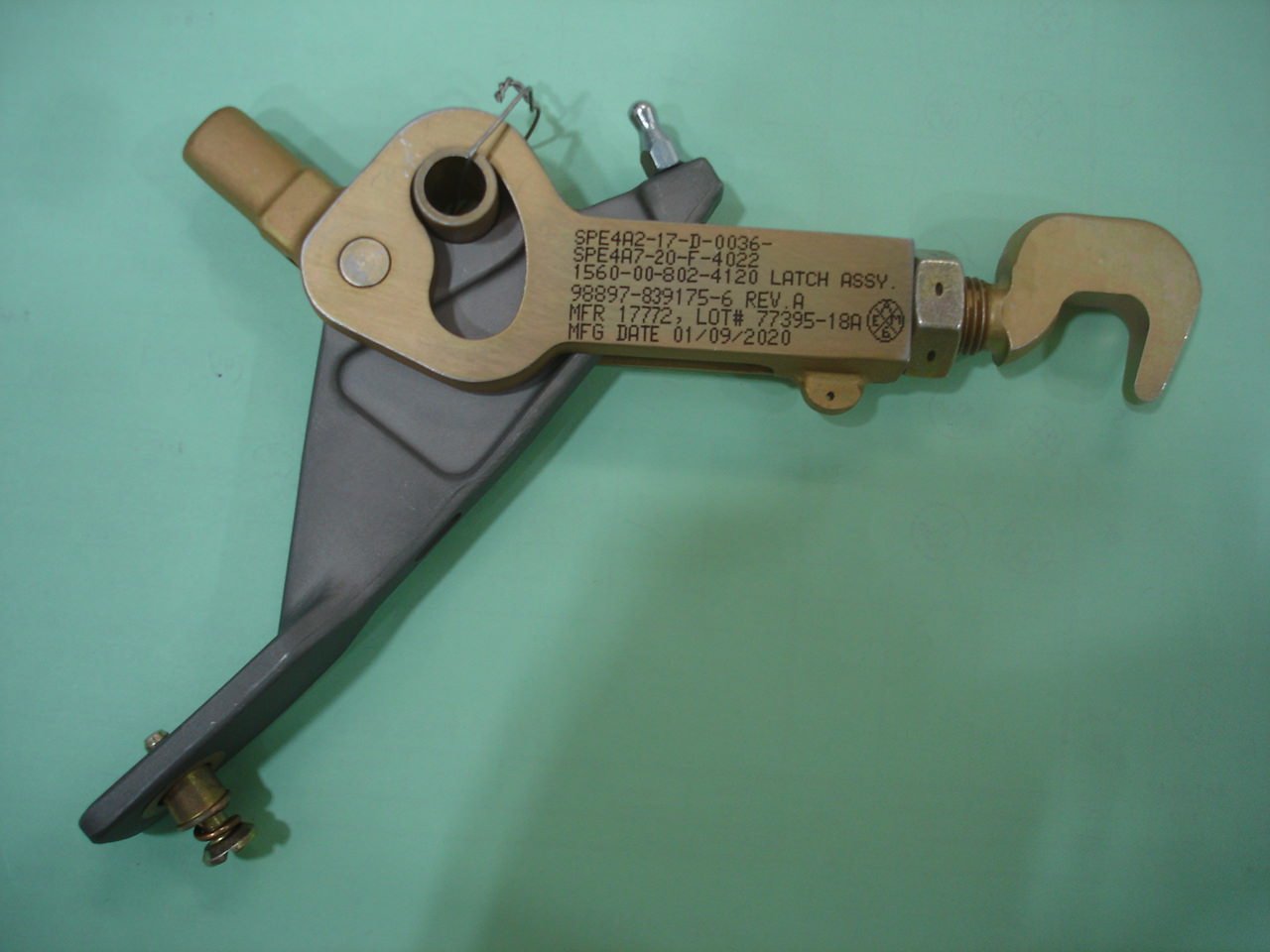

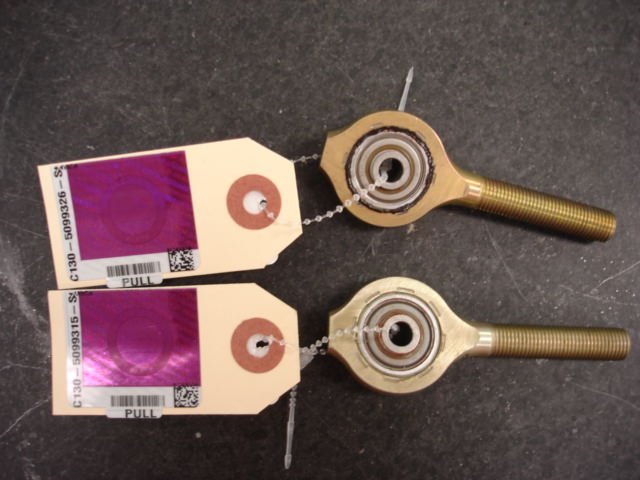

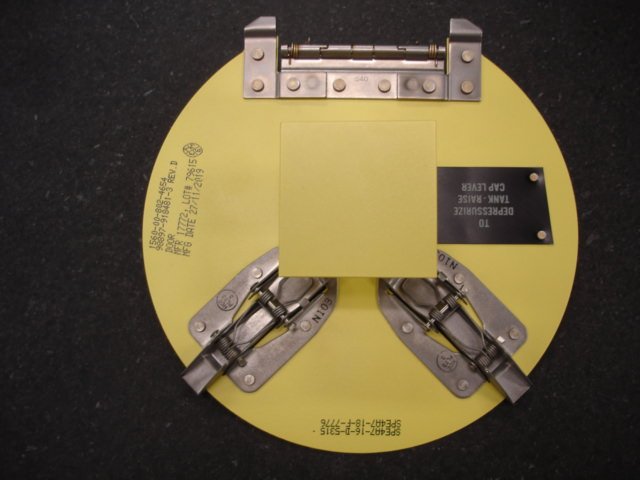

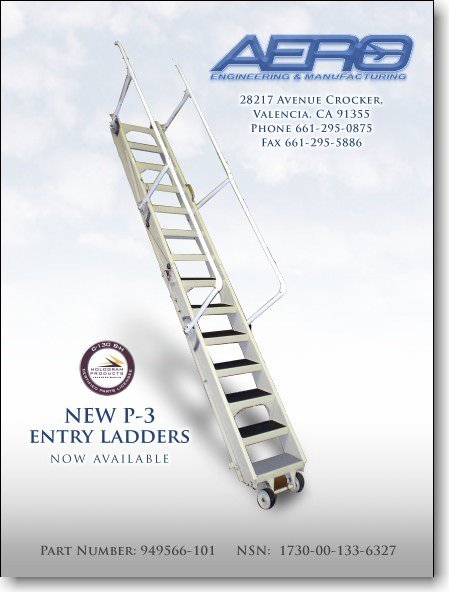

We hold product licensing and approval agreements for multiple platforms including, C5, F16, P-3, C-130 (B-H). We also maintain current OEM production on over 300 C-130 and F-16 part numbers.

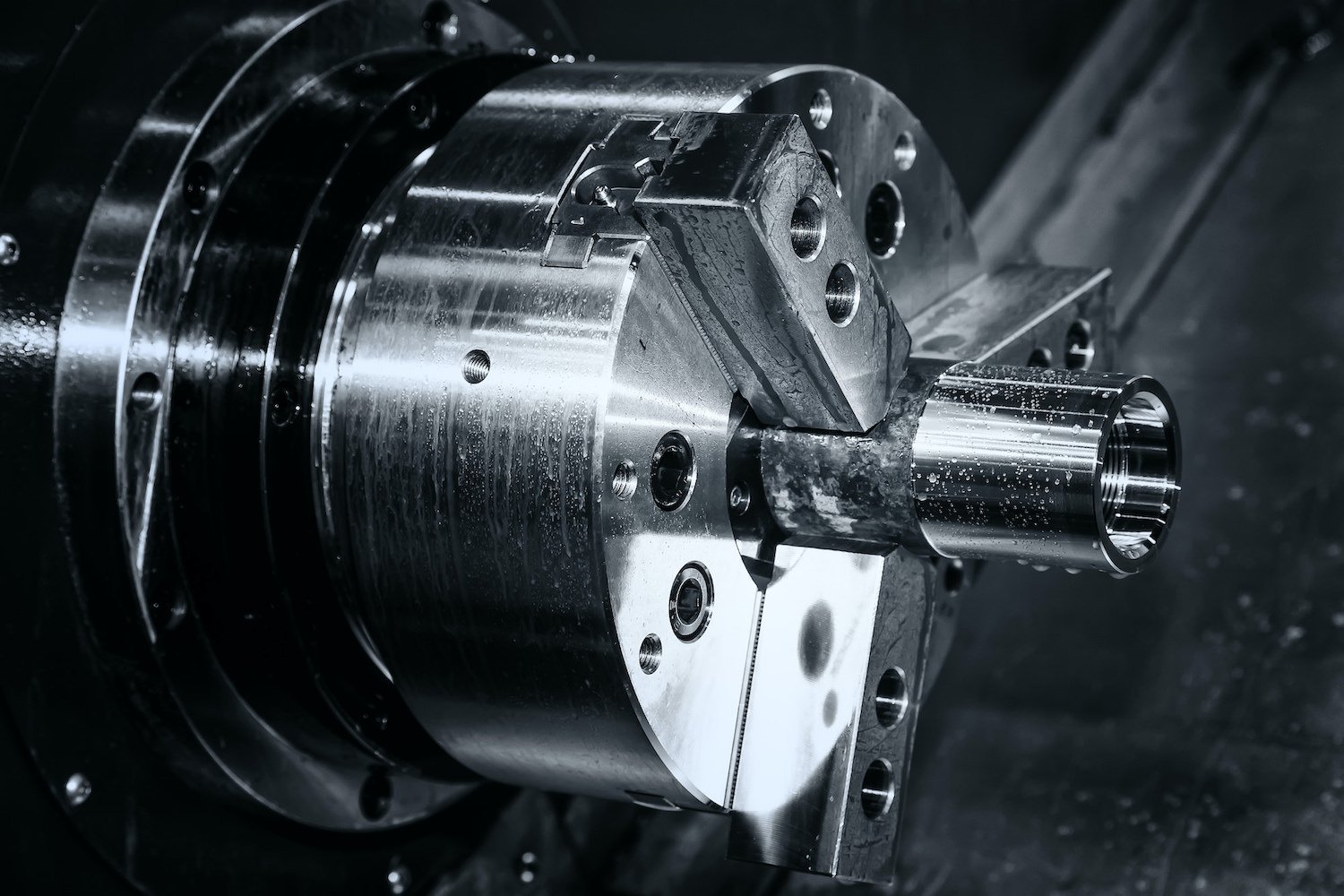

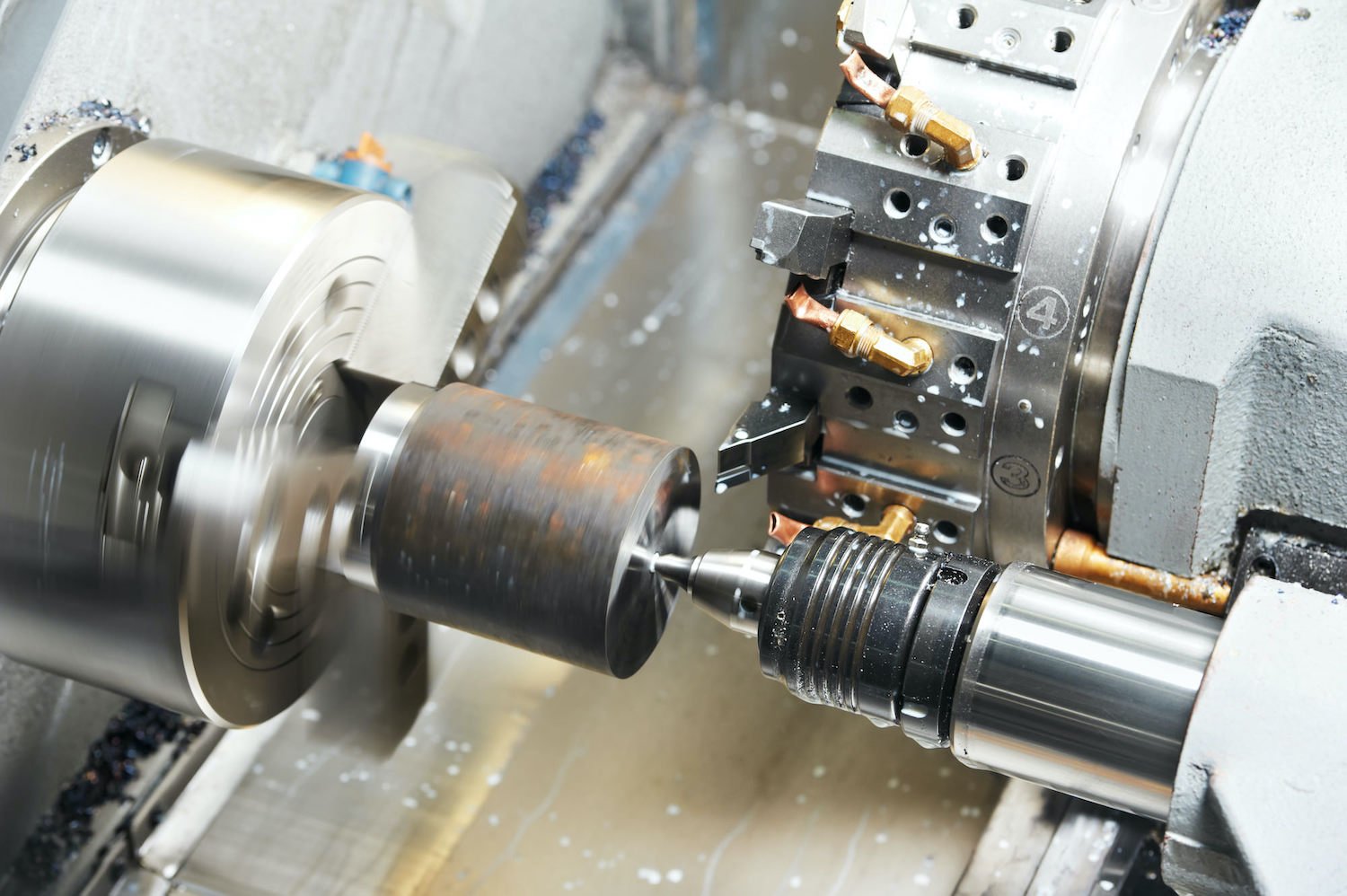

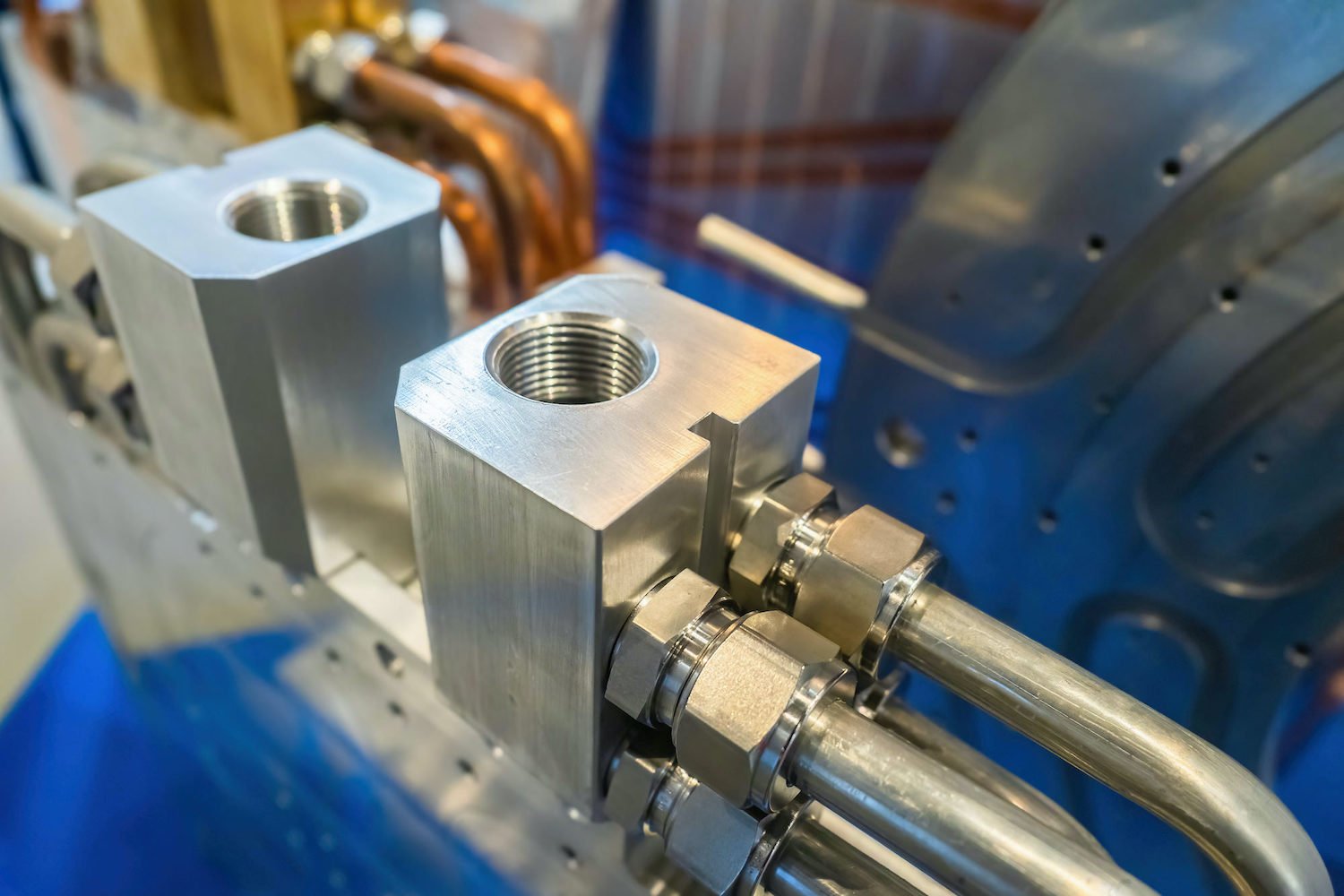

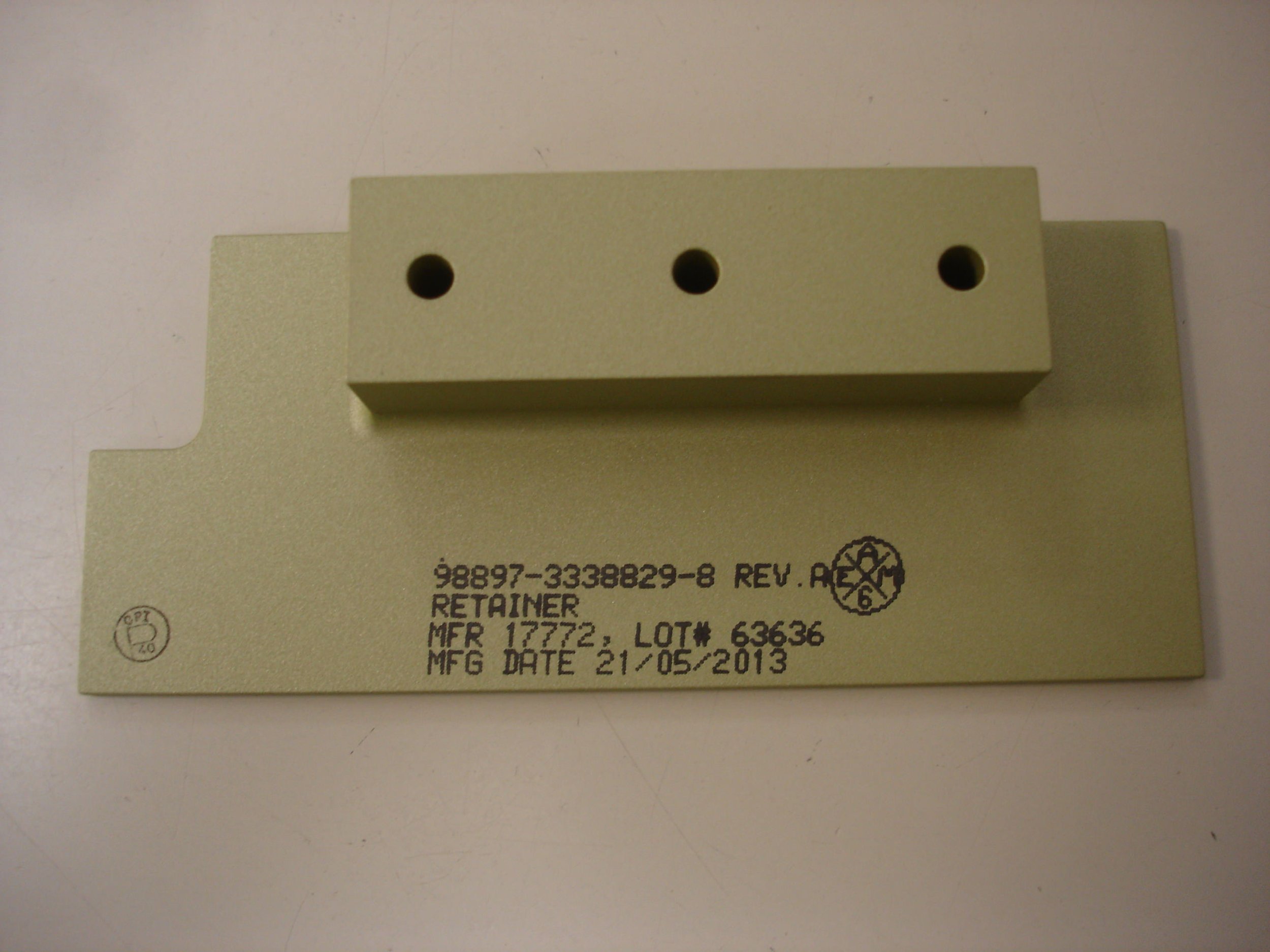

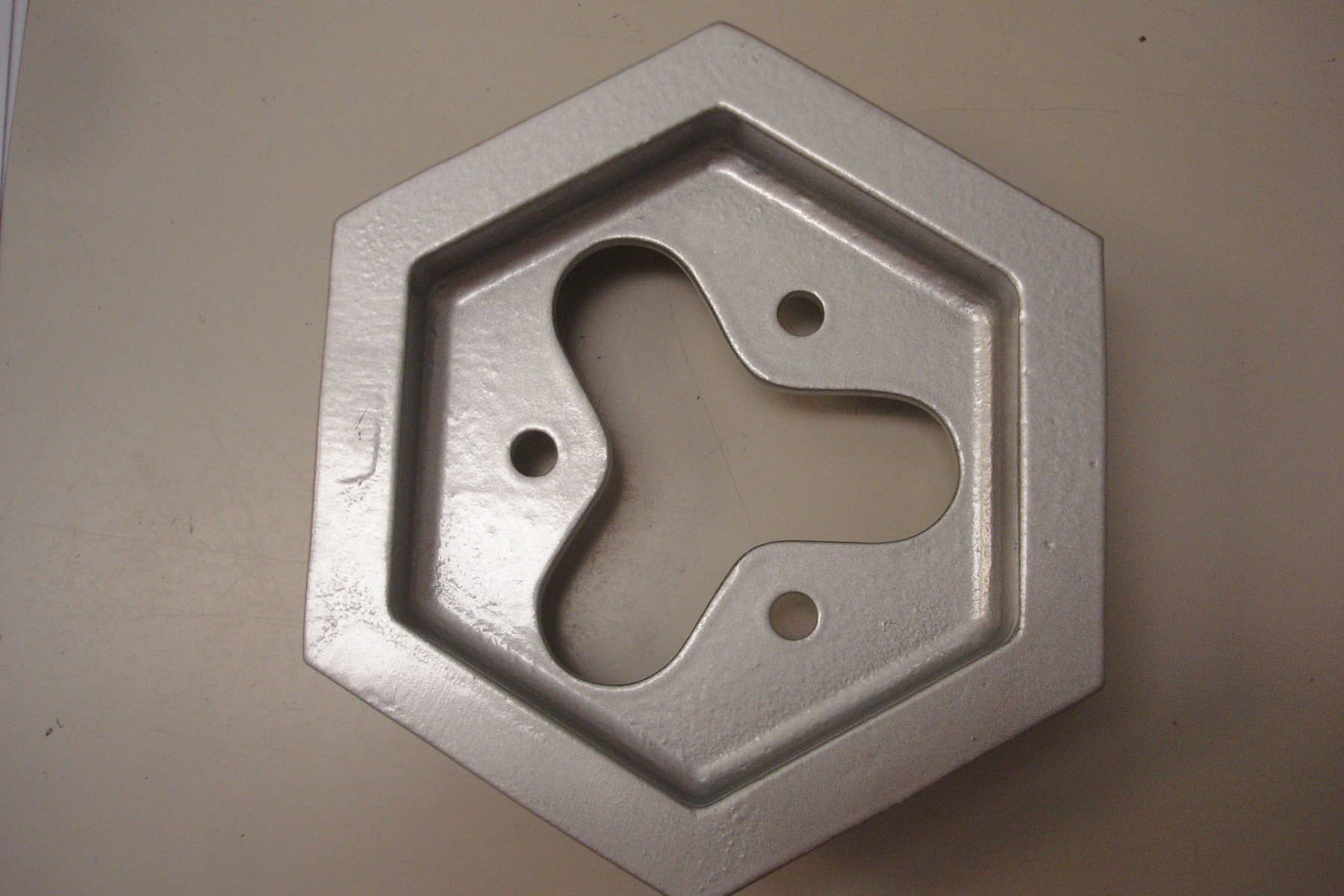

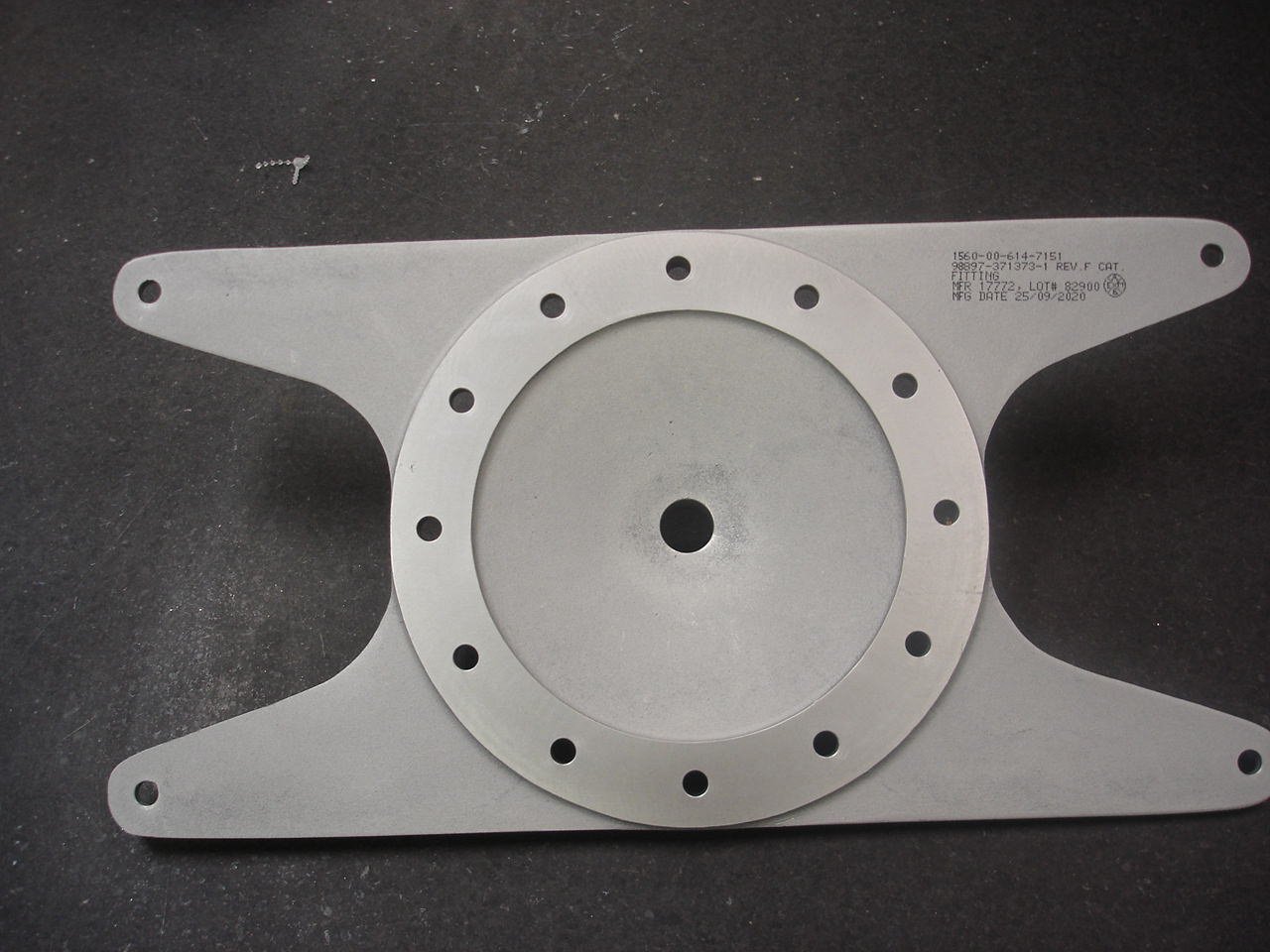

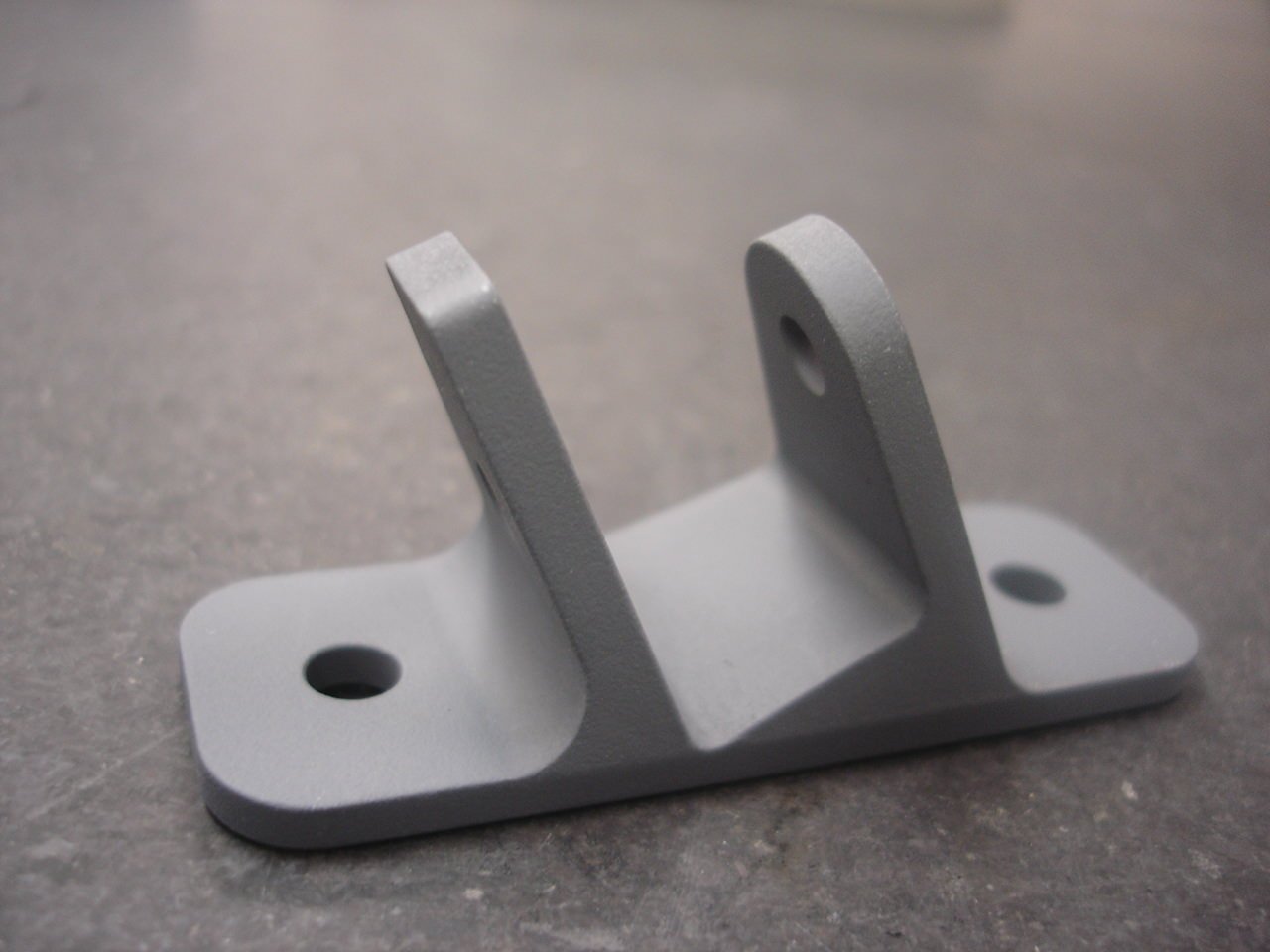

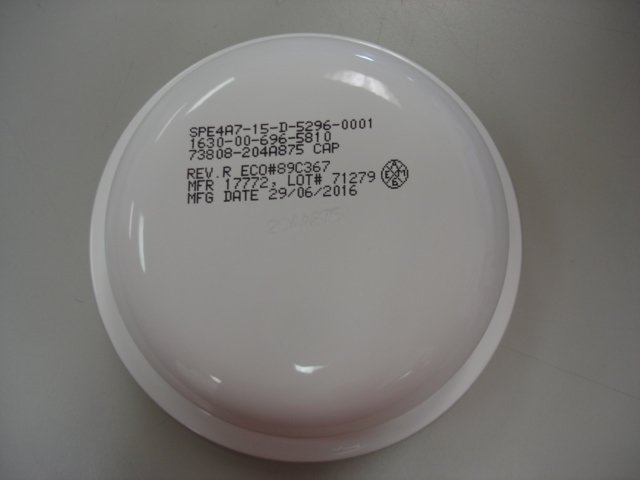

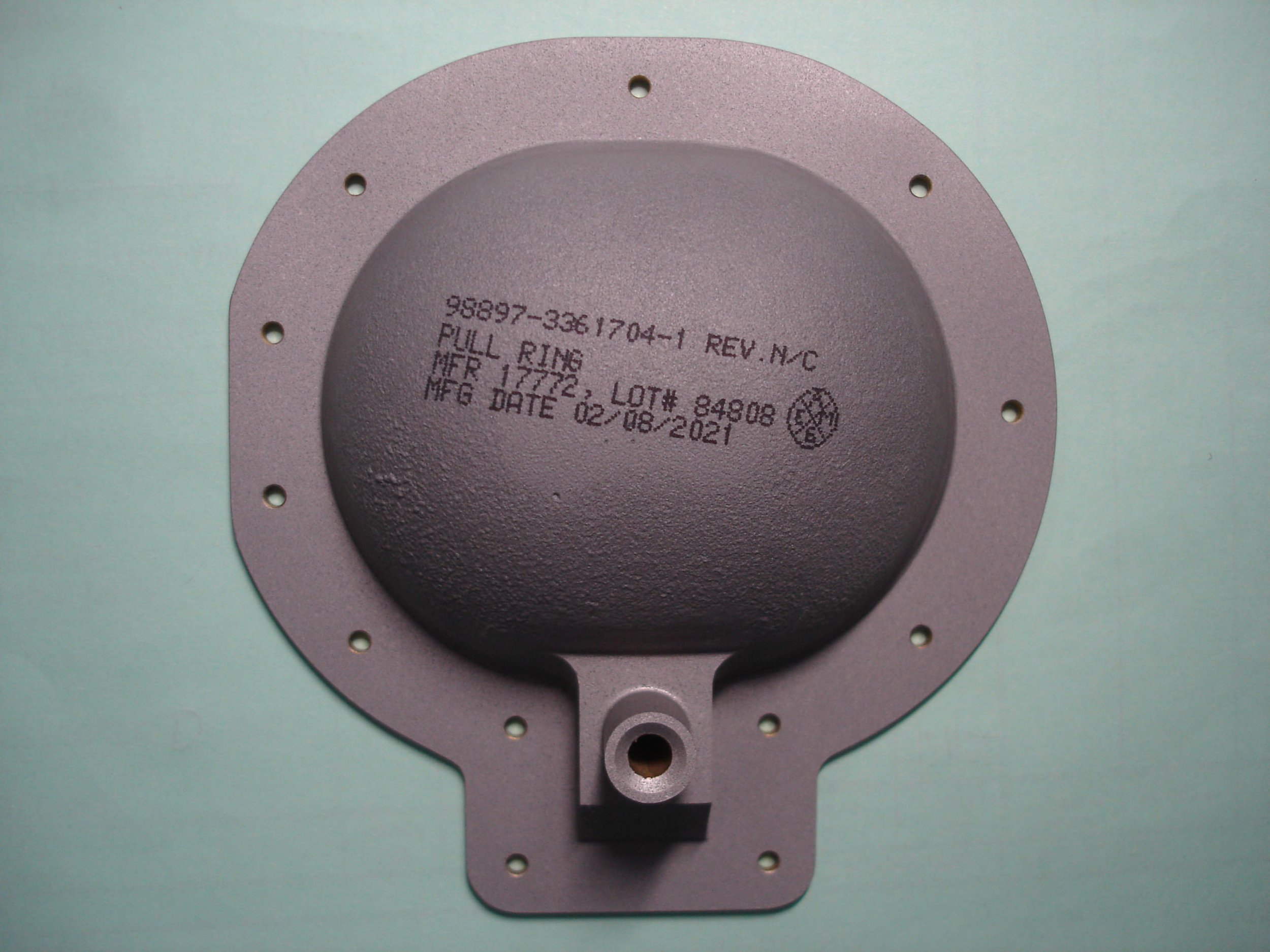

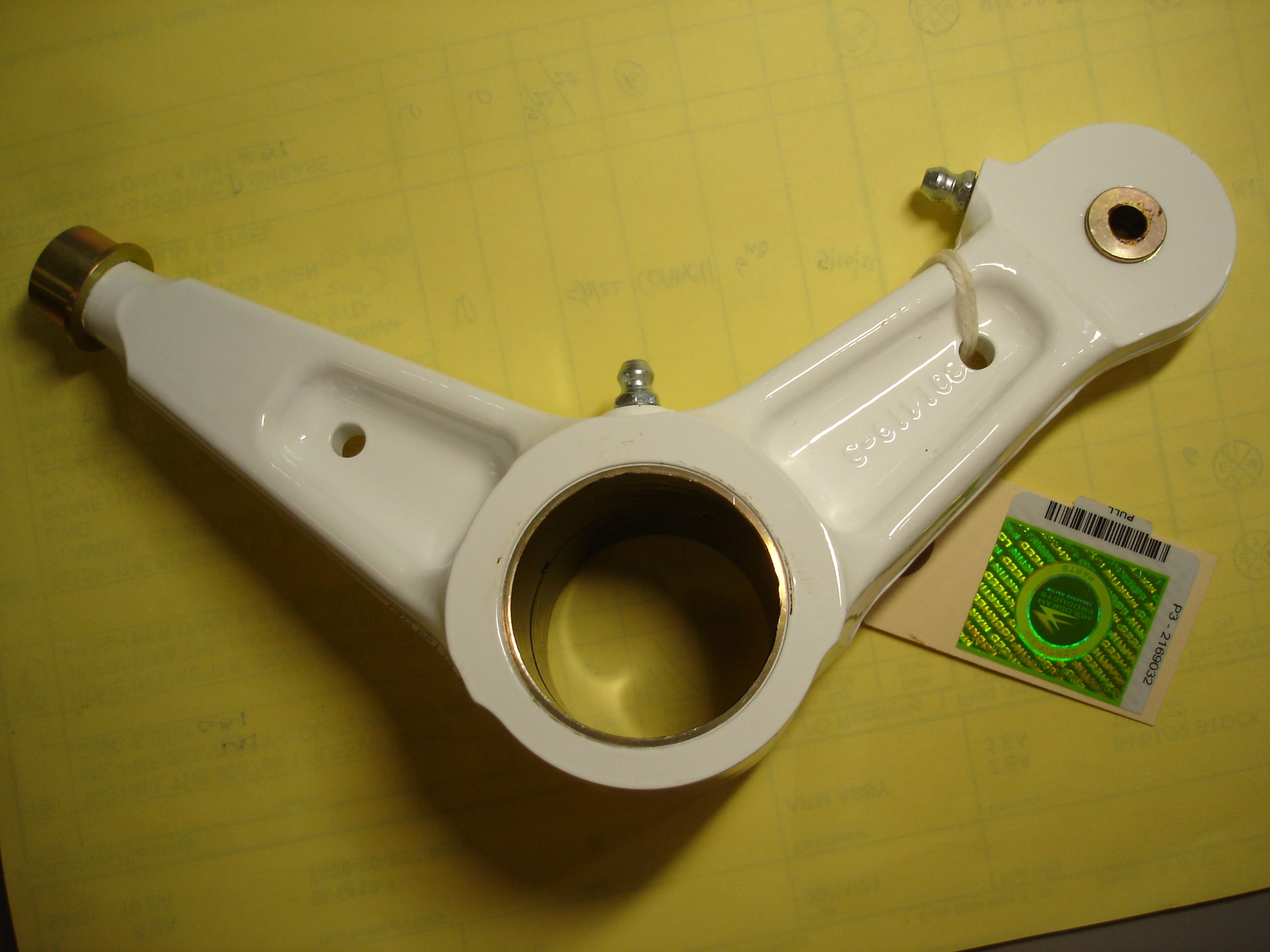

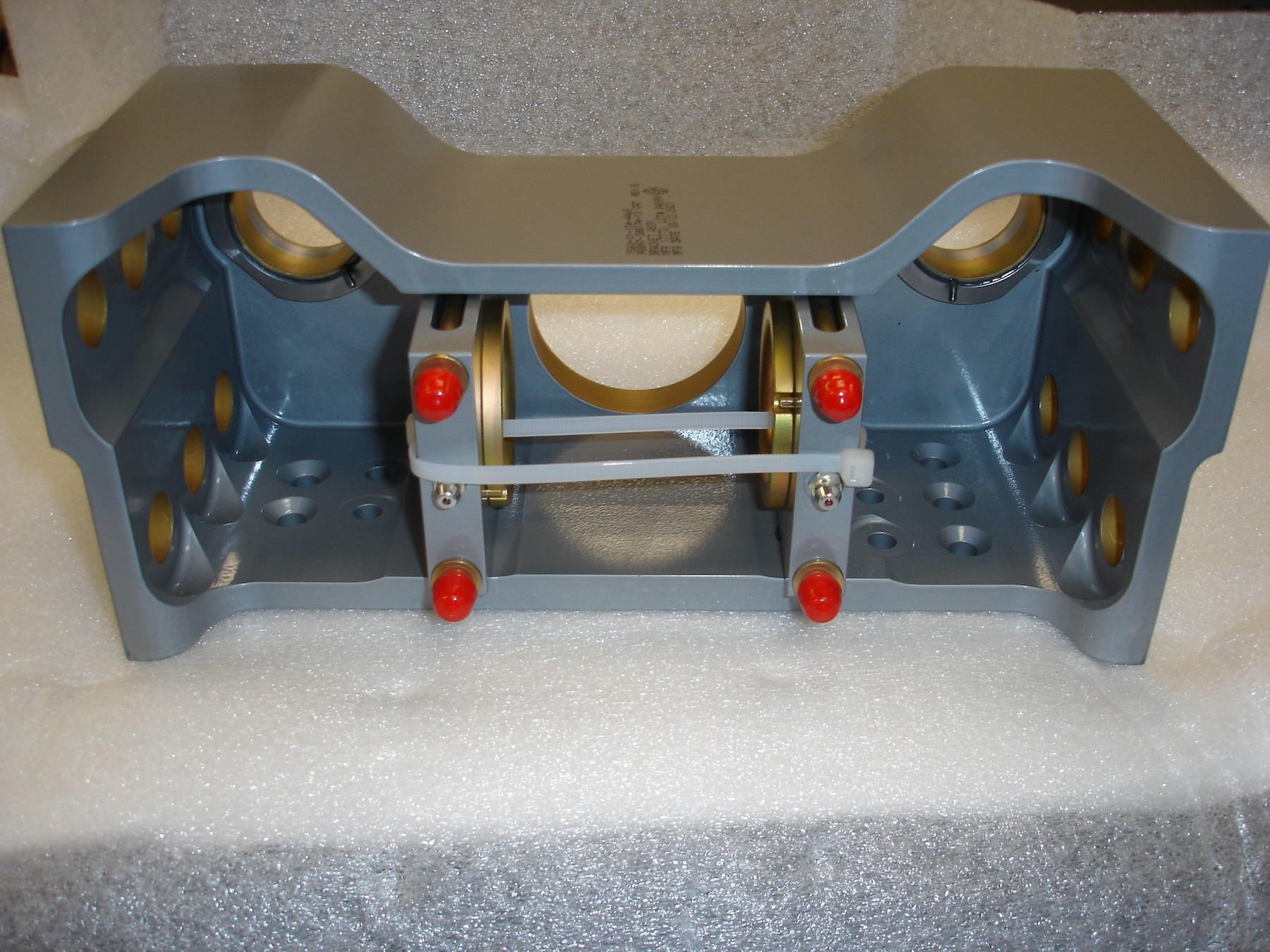

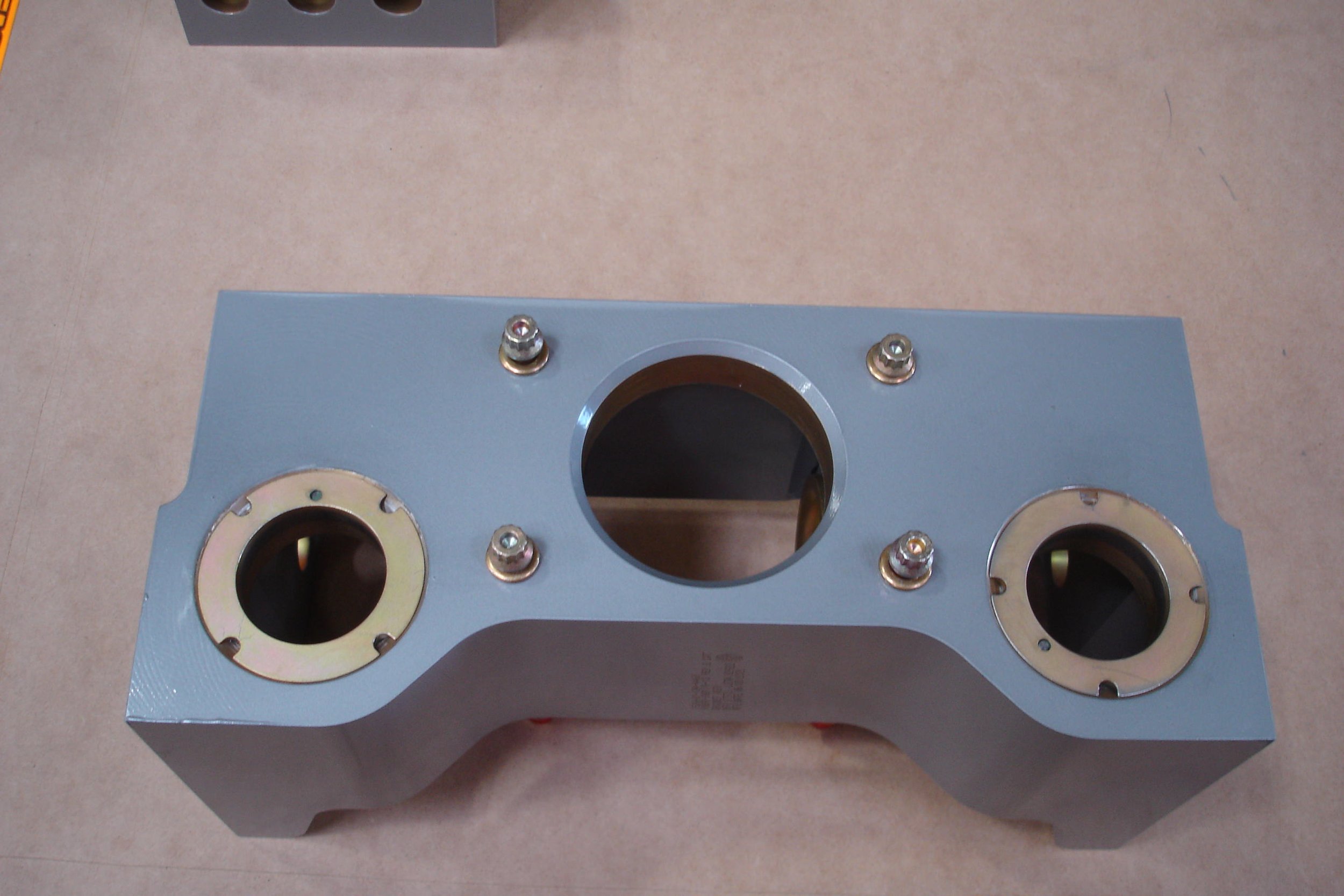

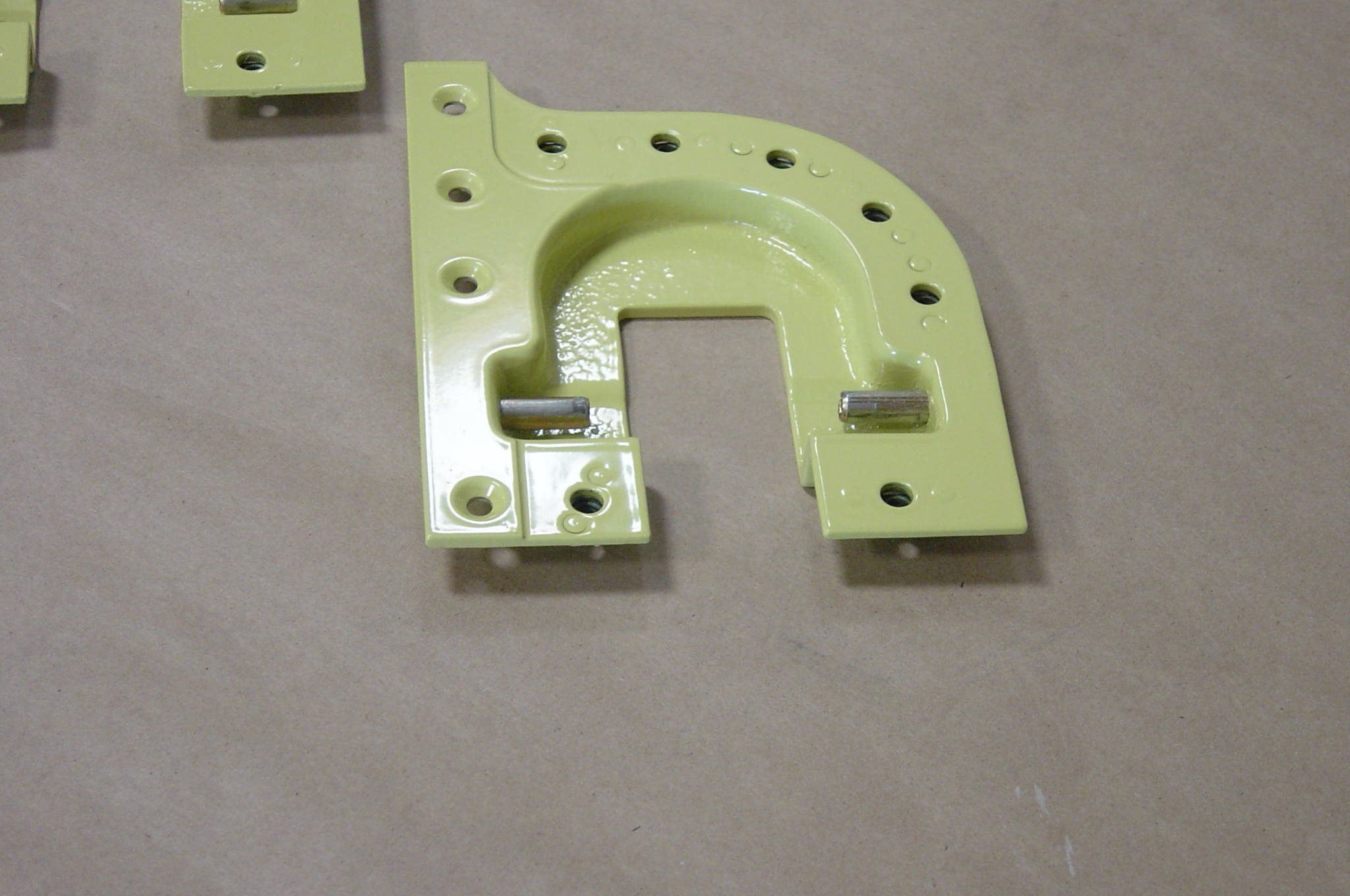

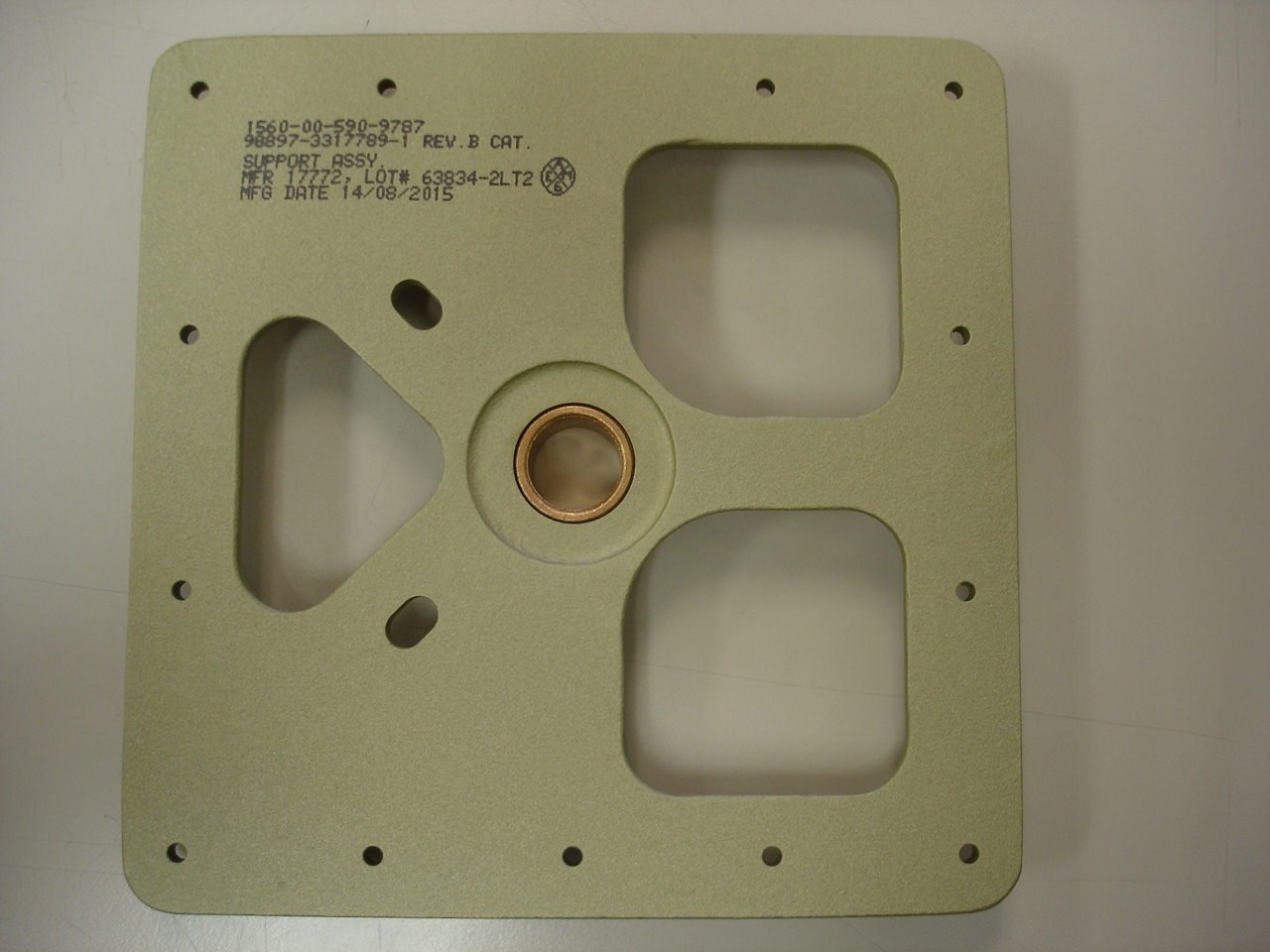

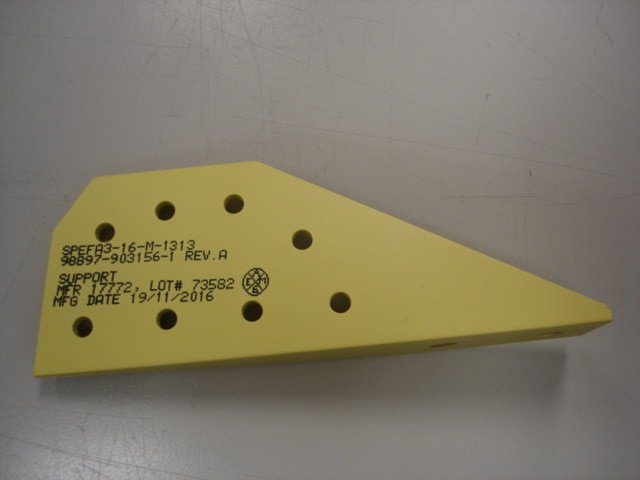

CNC Machining

3 and 4 axis CNC mill envelope up to 50”x30”x30” depending on configuration

2 axis CNC turning envelope of up to 15” diameter and 36” OD turning

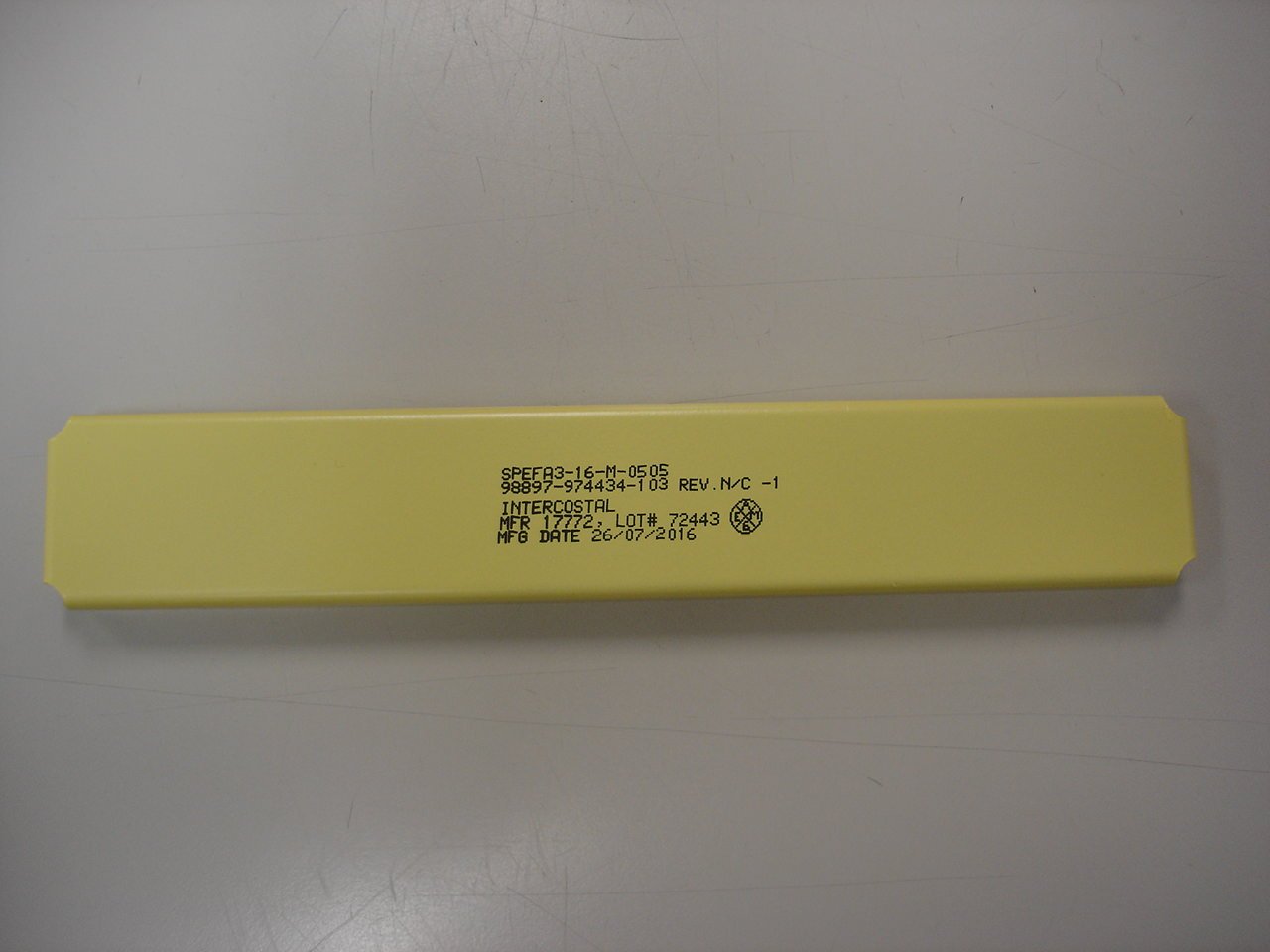

Common materials: Alloy steel, Stainless steel, Aluminum, Titanium, brass/bronze, and engineering plastics

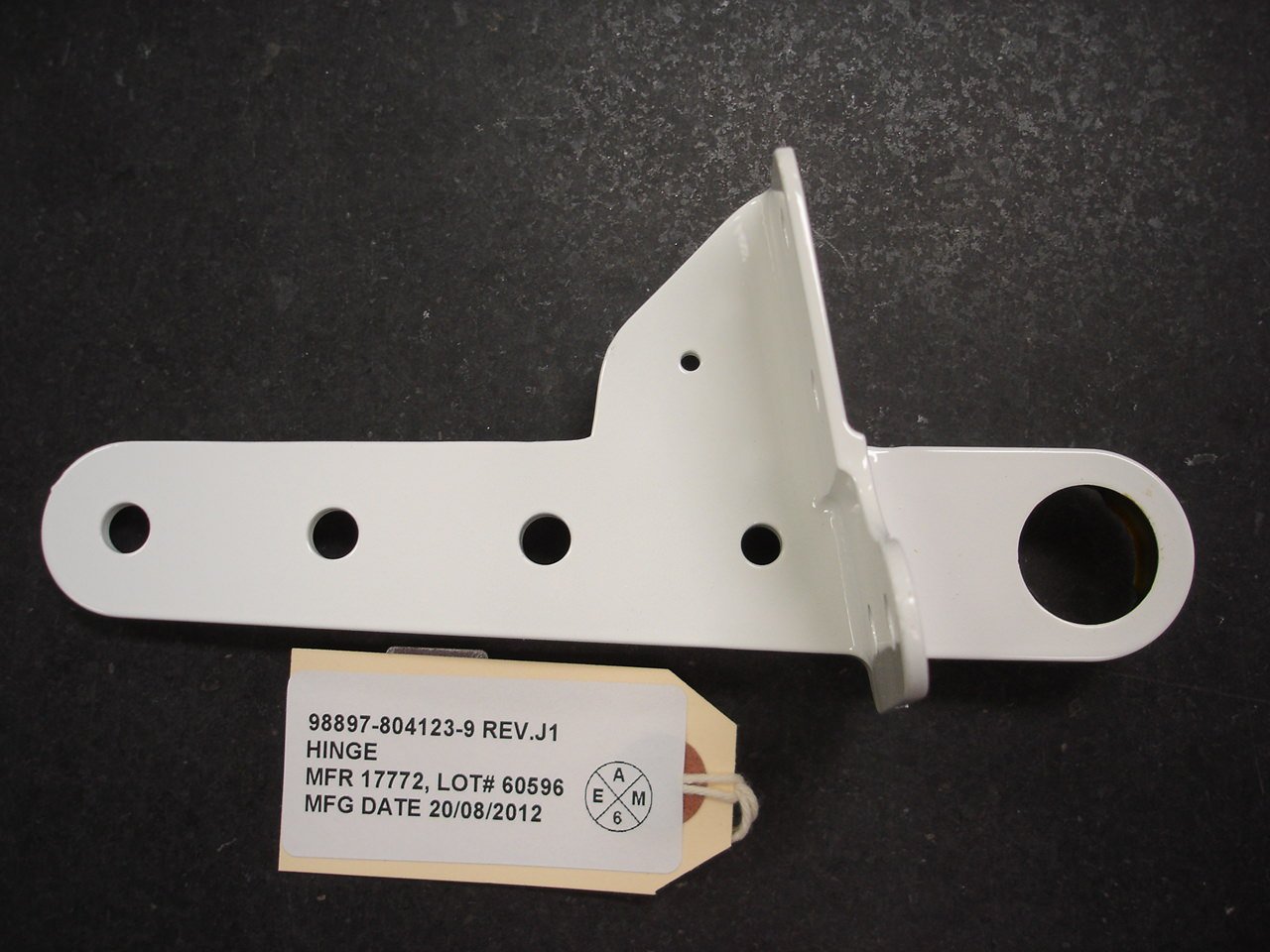

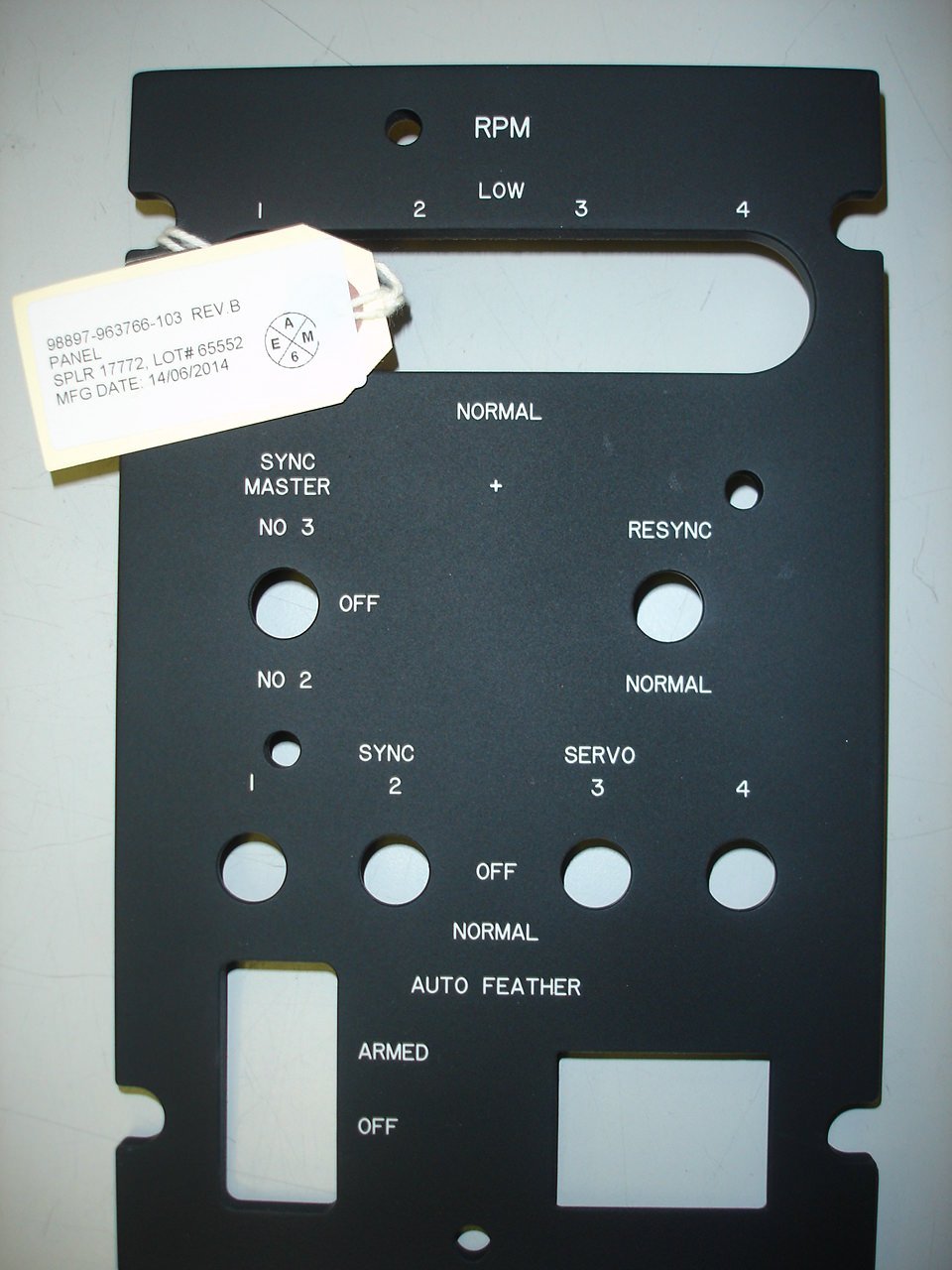

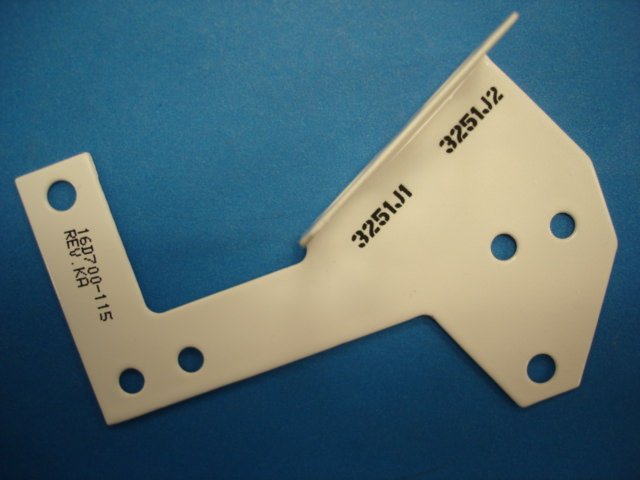

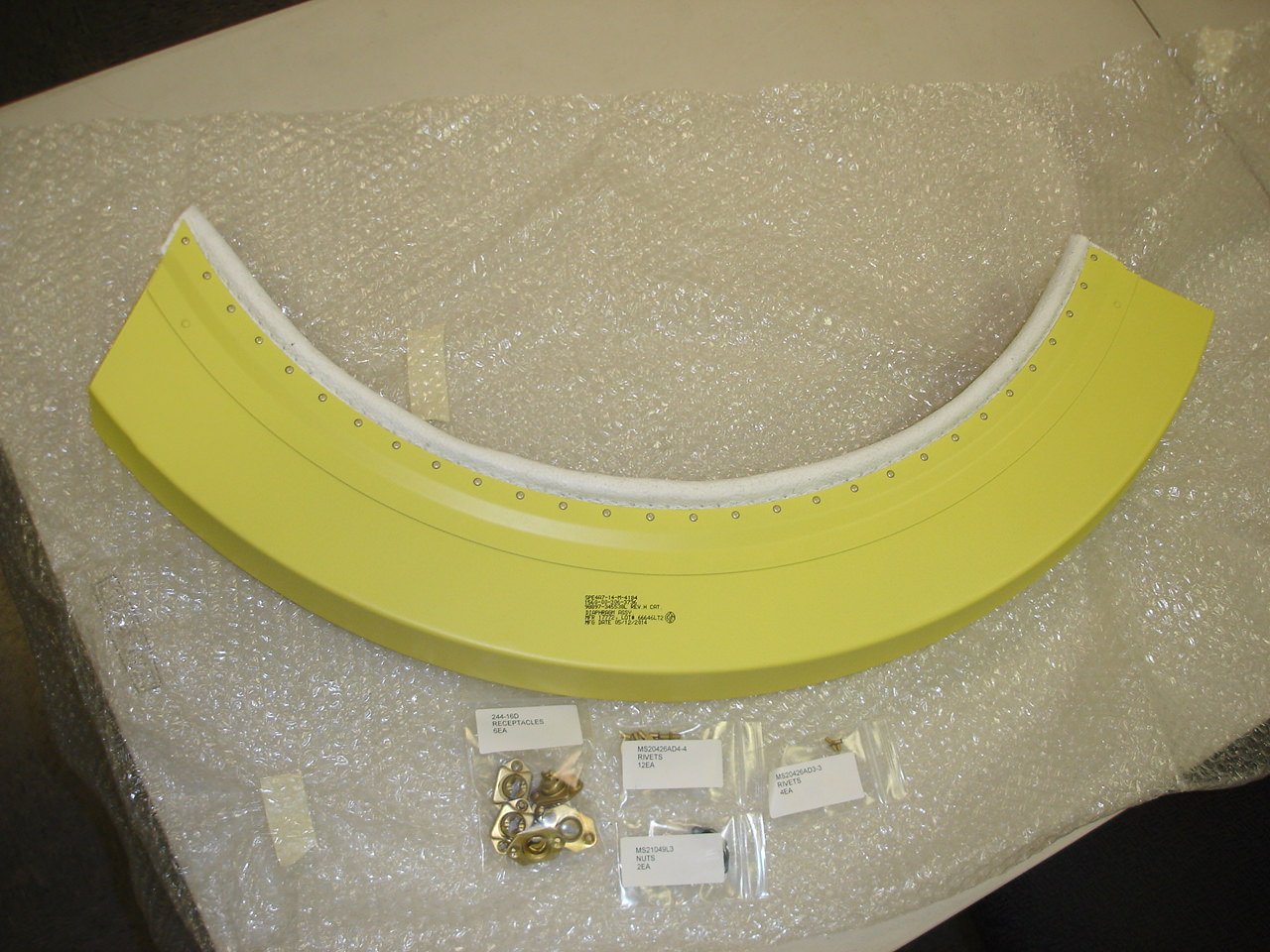

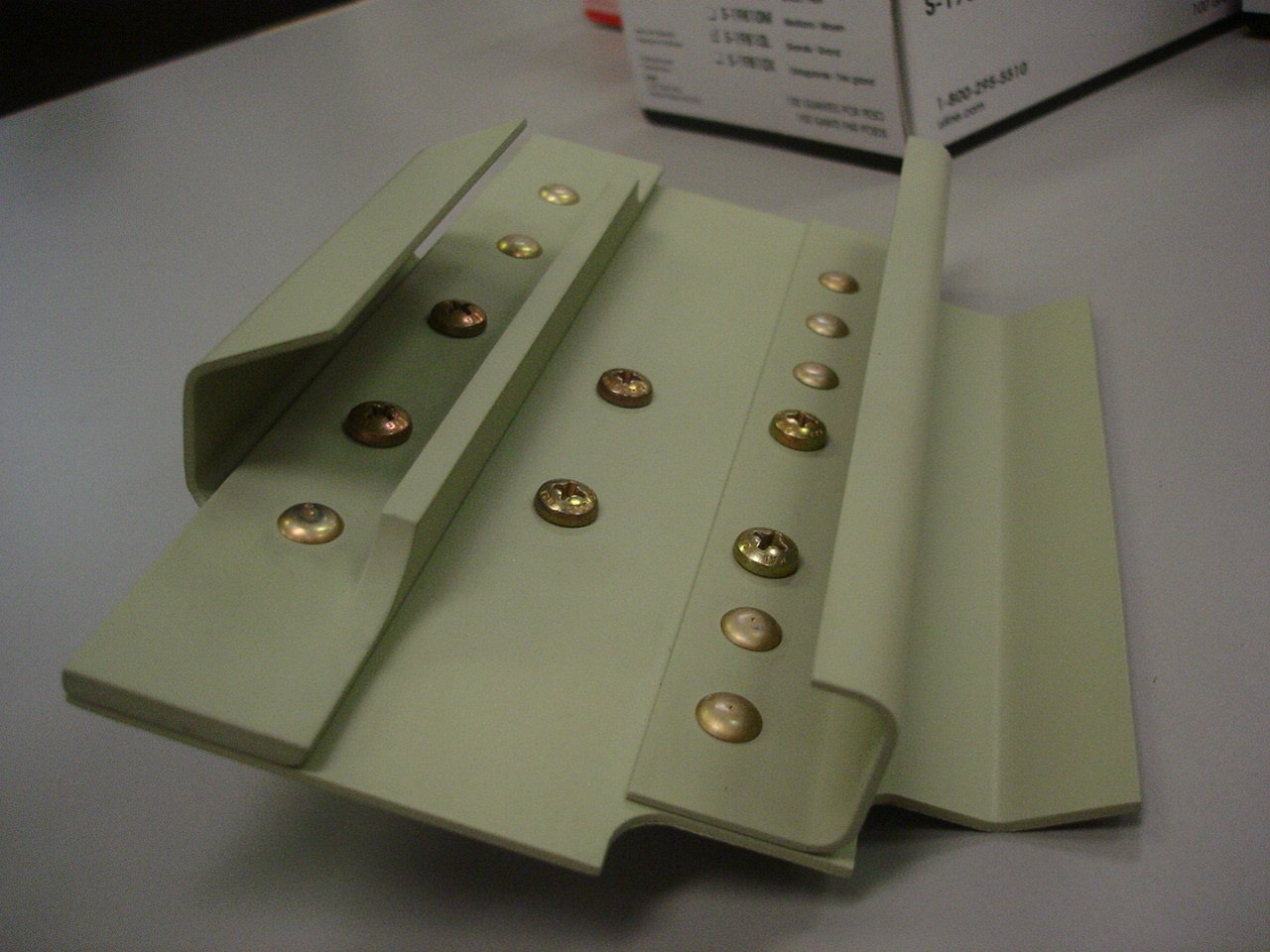

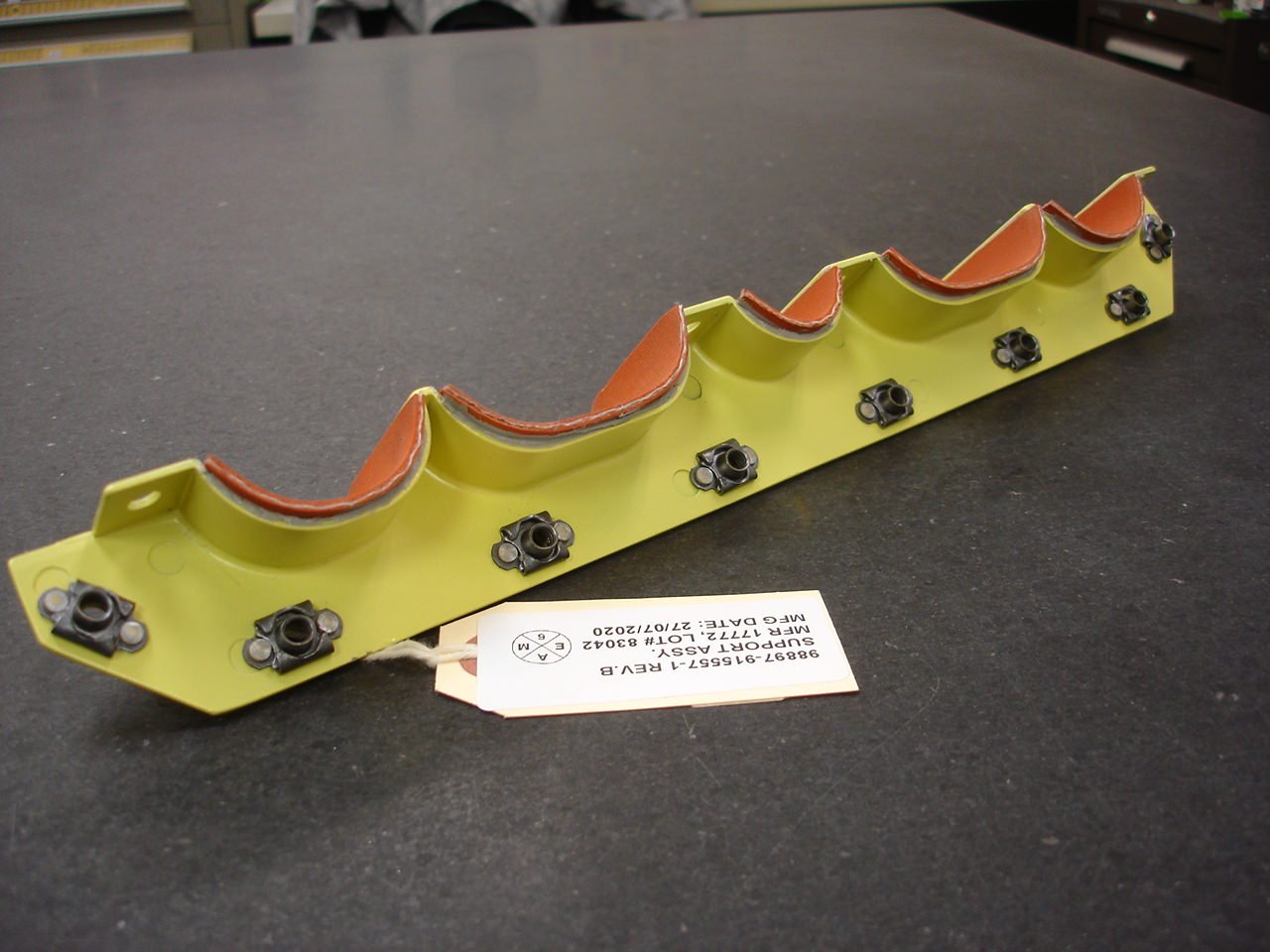

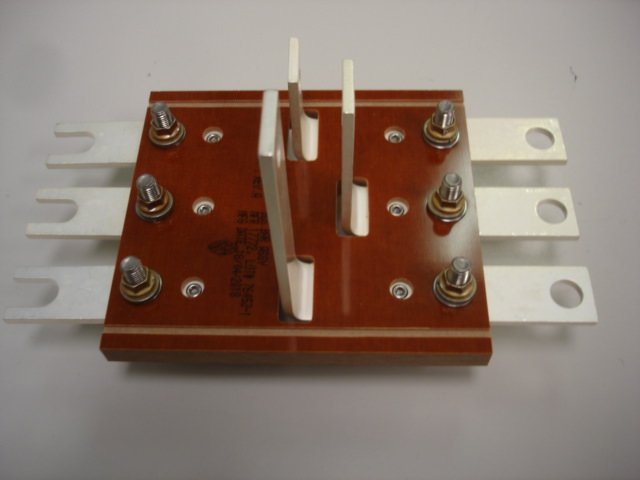

Sheet Metal

Water Jet capabilities up to 36”x 50” x 5” thick

Bending and forming up to 96” wide and ¼” thick

Common materials: Alloy steel, stainless steel, aluminum, clad aluminum, and various soft metals

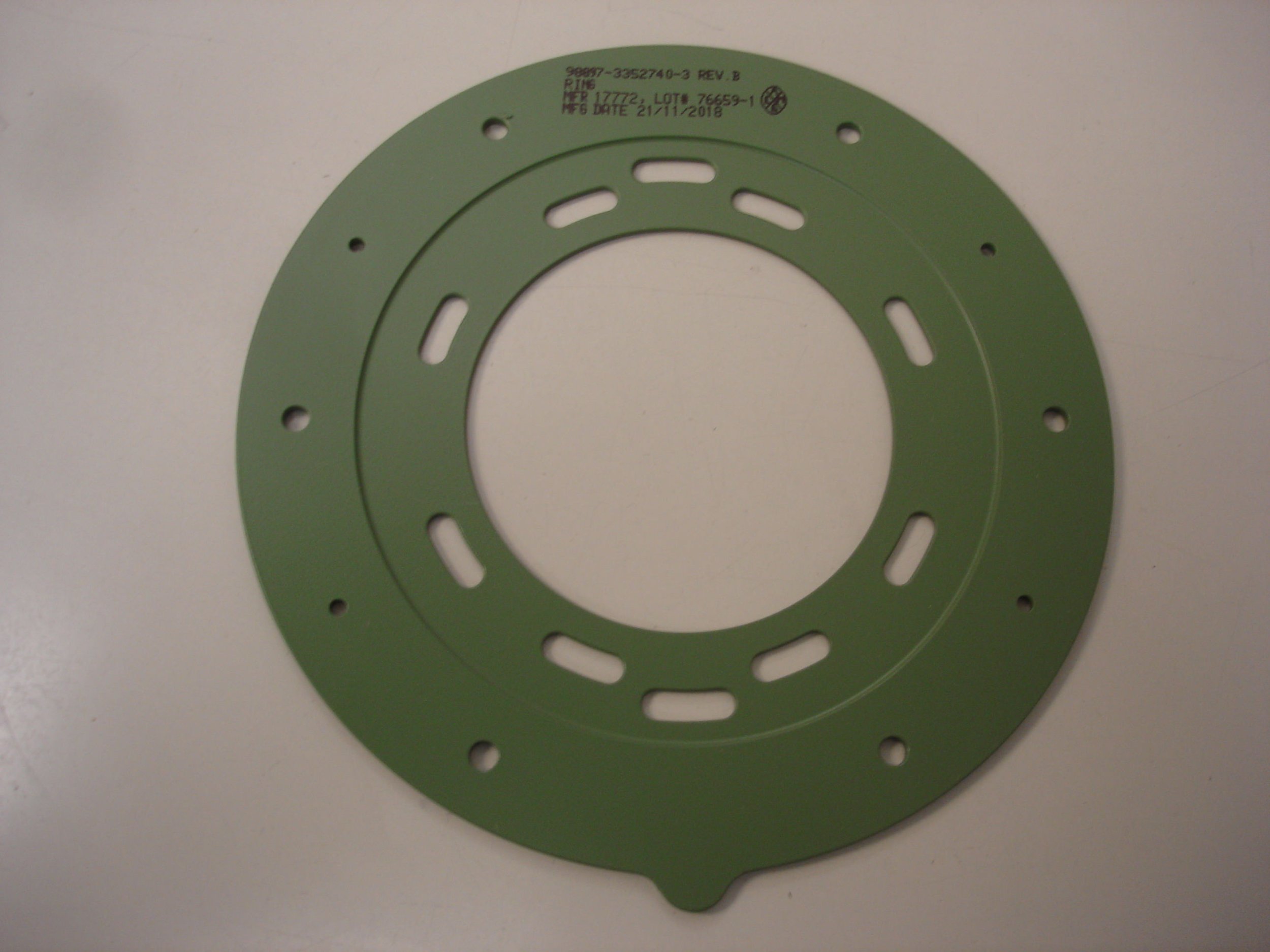

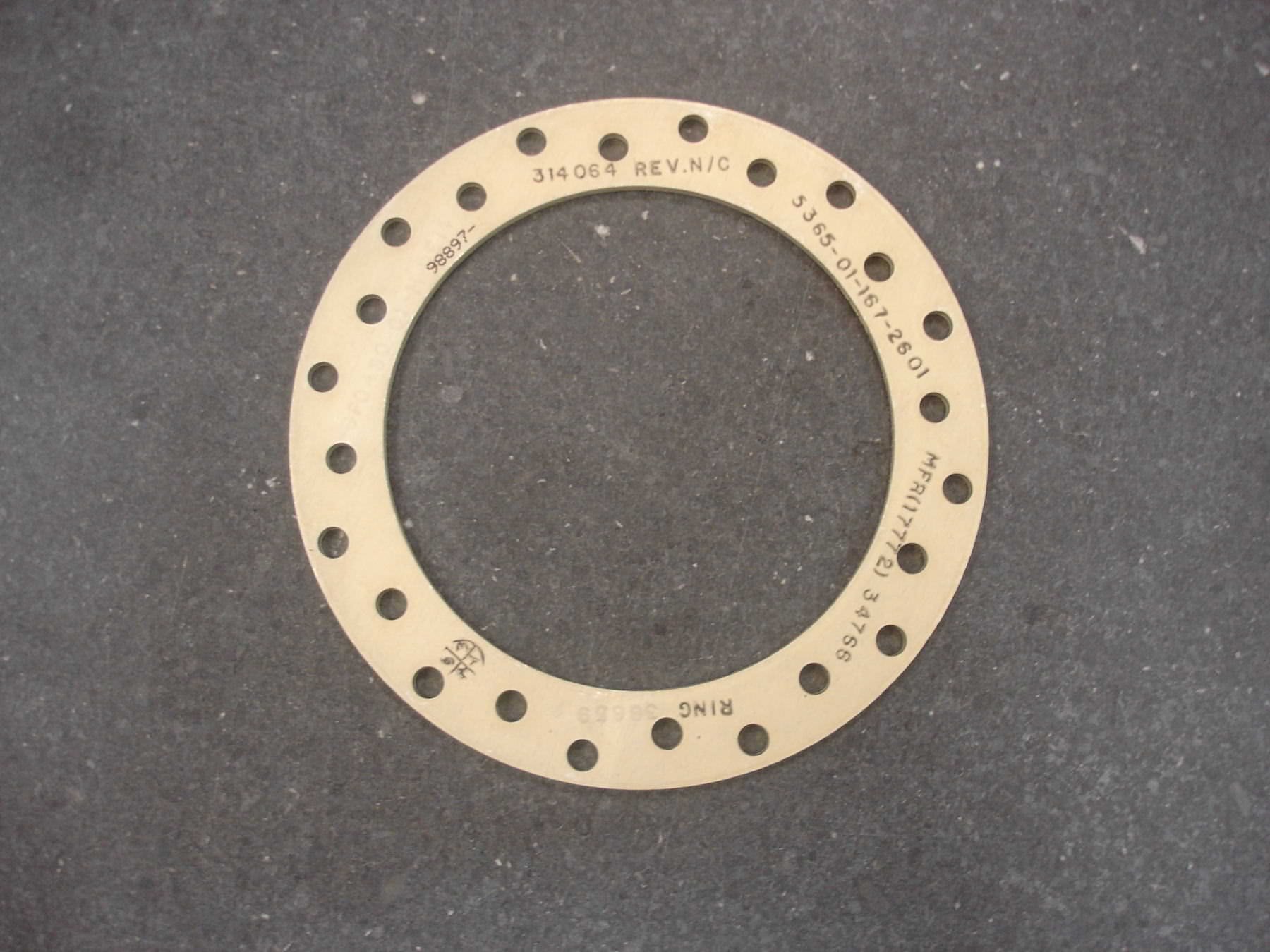

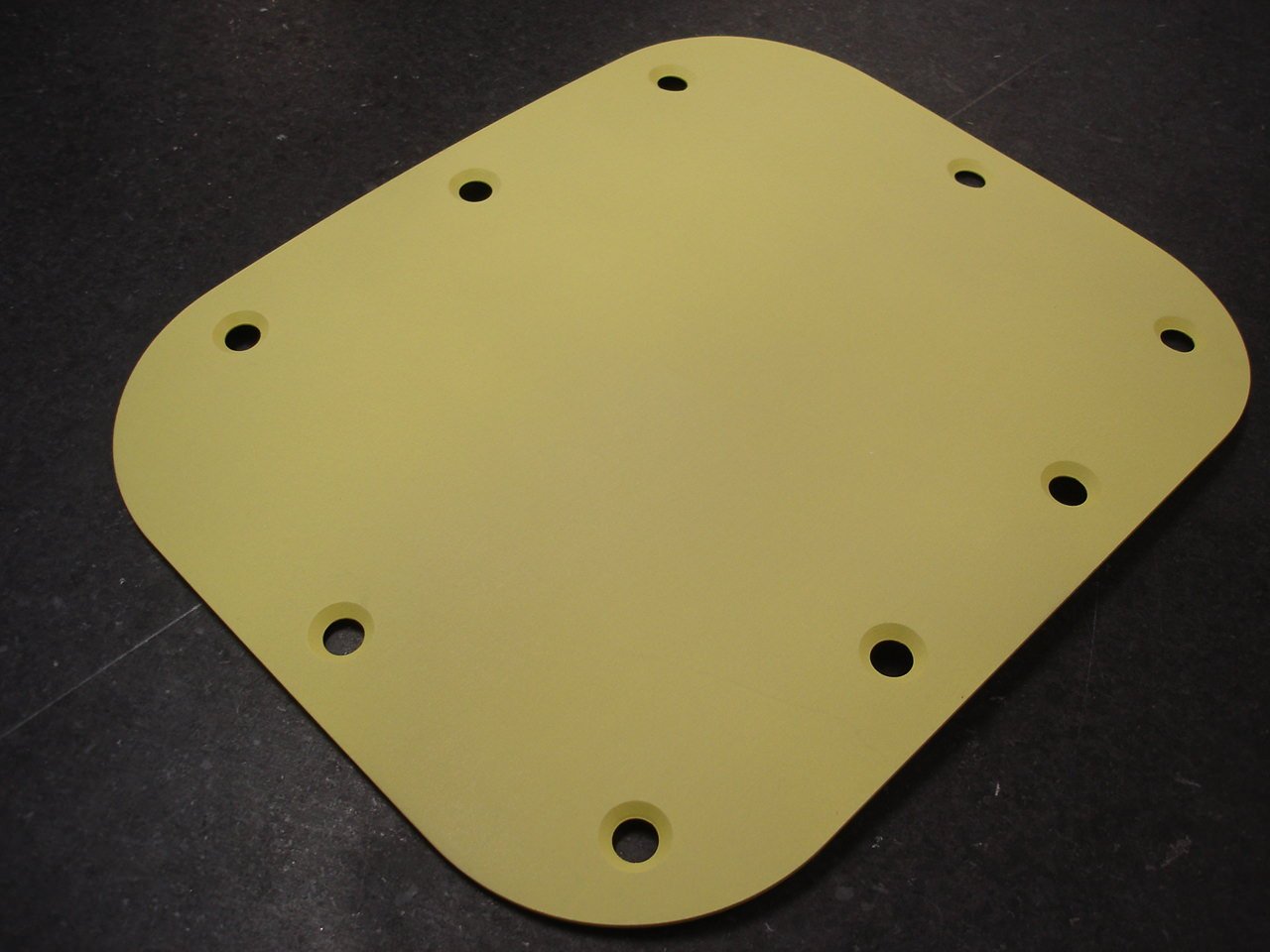

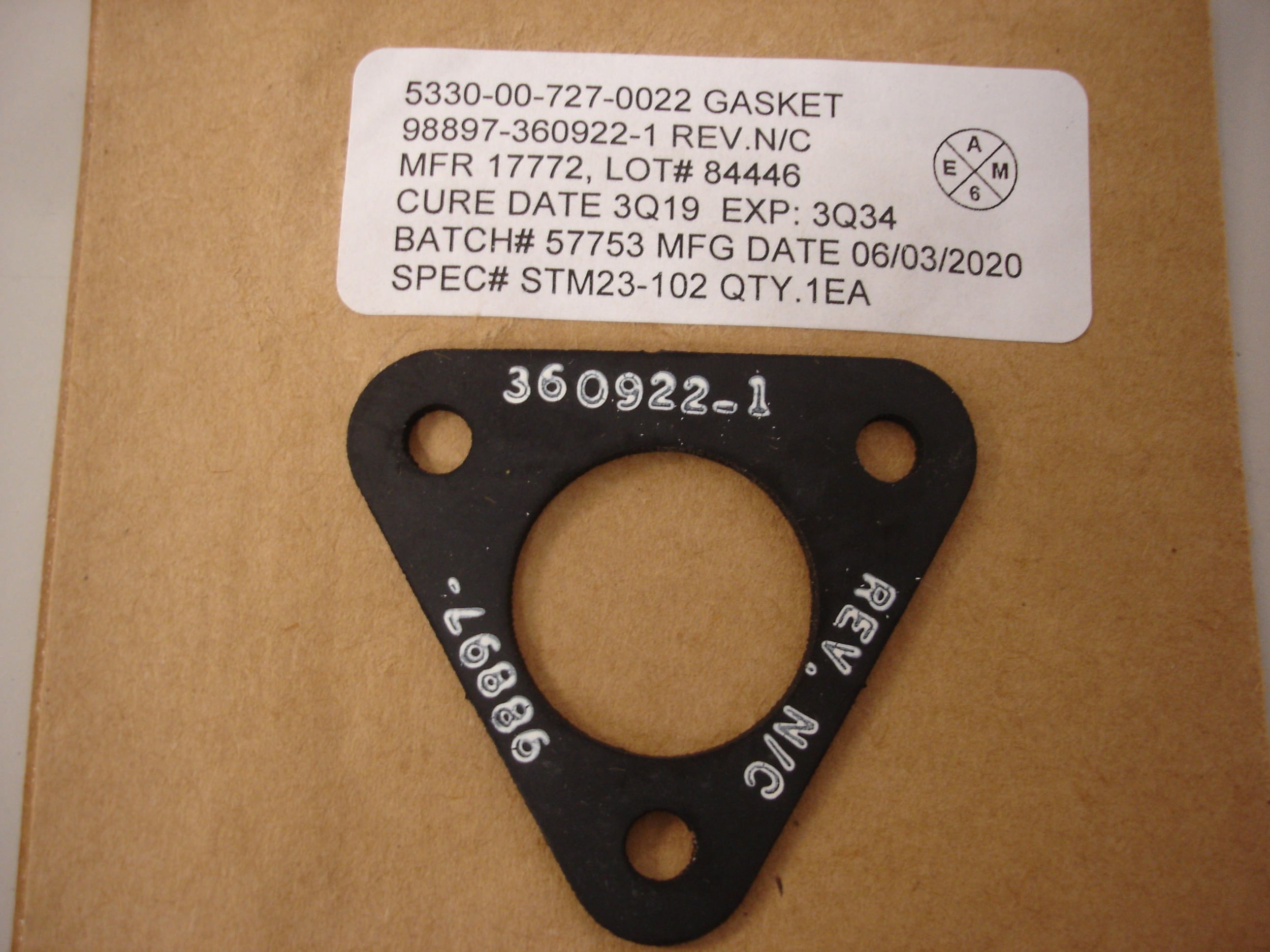

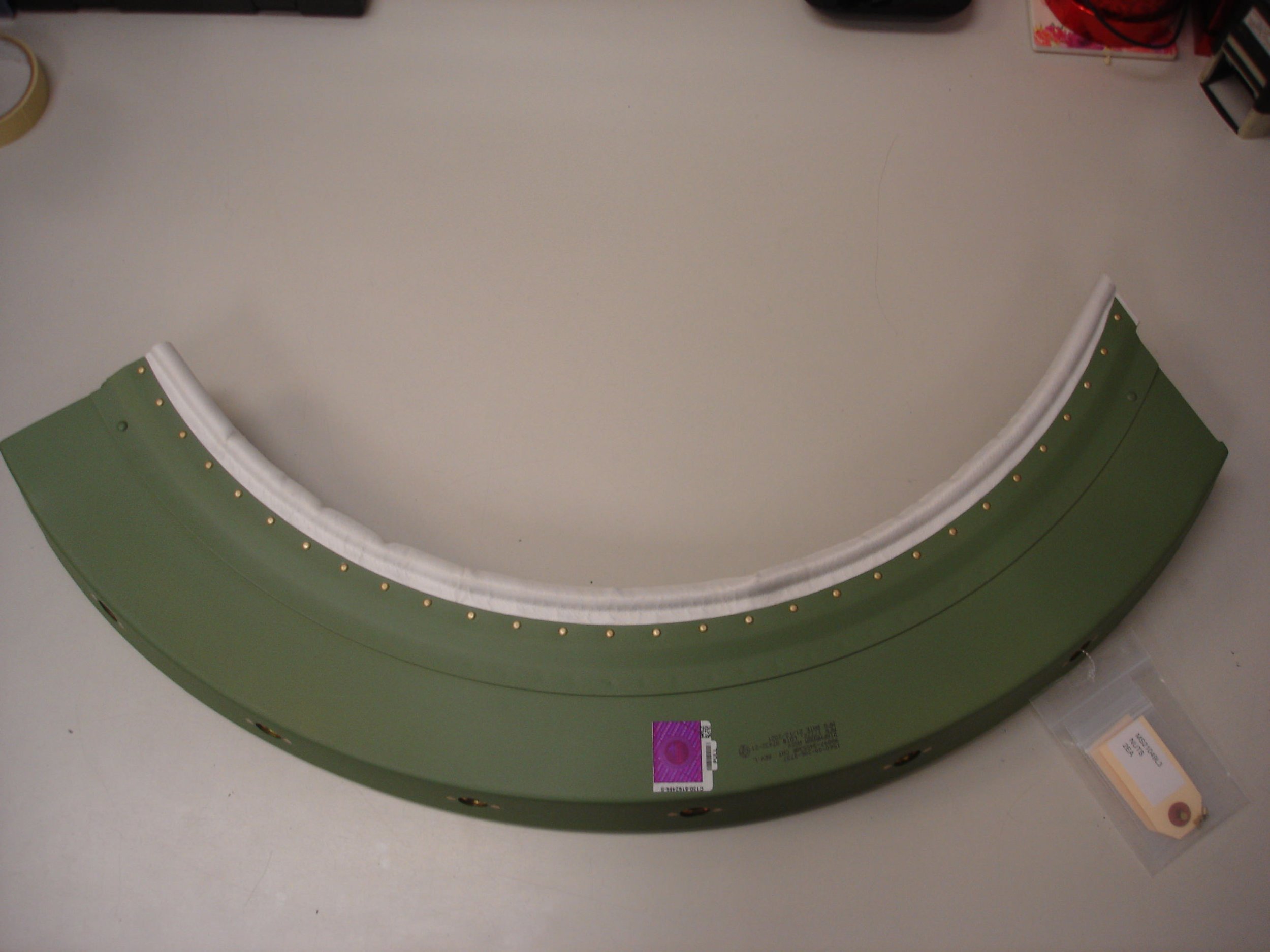

Cut Gasket Fabrication

Water Jet capabilities up to 36”x 50” x 5” thick

Bending and forming up to 96” wide and ¼” thick

Common materials: Metallic, rubber, textile, elastomeric and other non-metallic materials

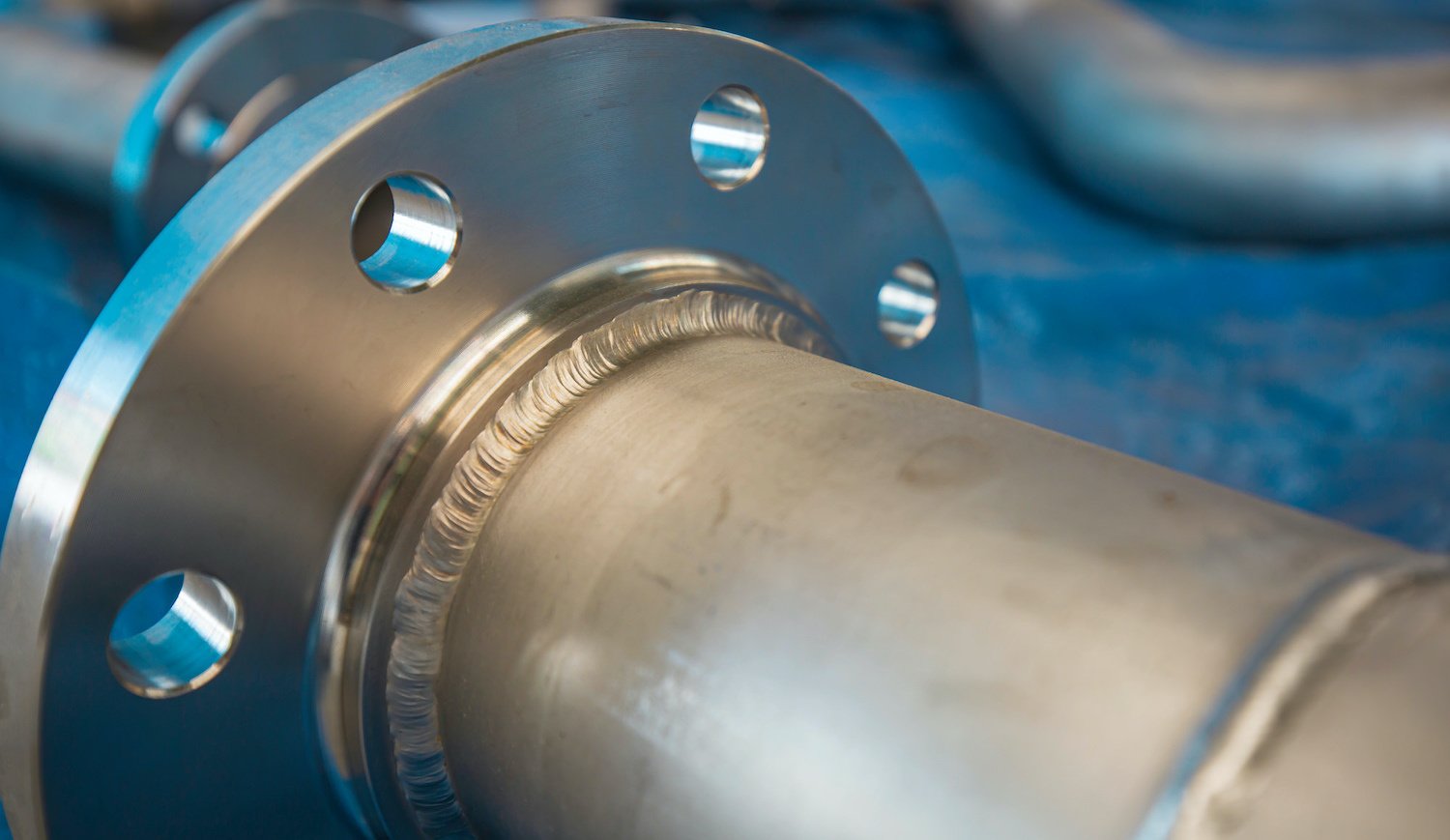

Welding

Alloy steels, stainless steels, titanium, and aluminum

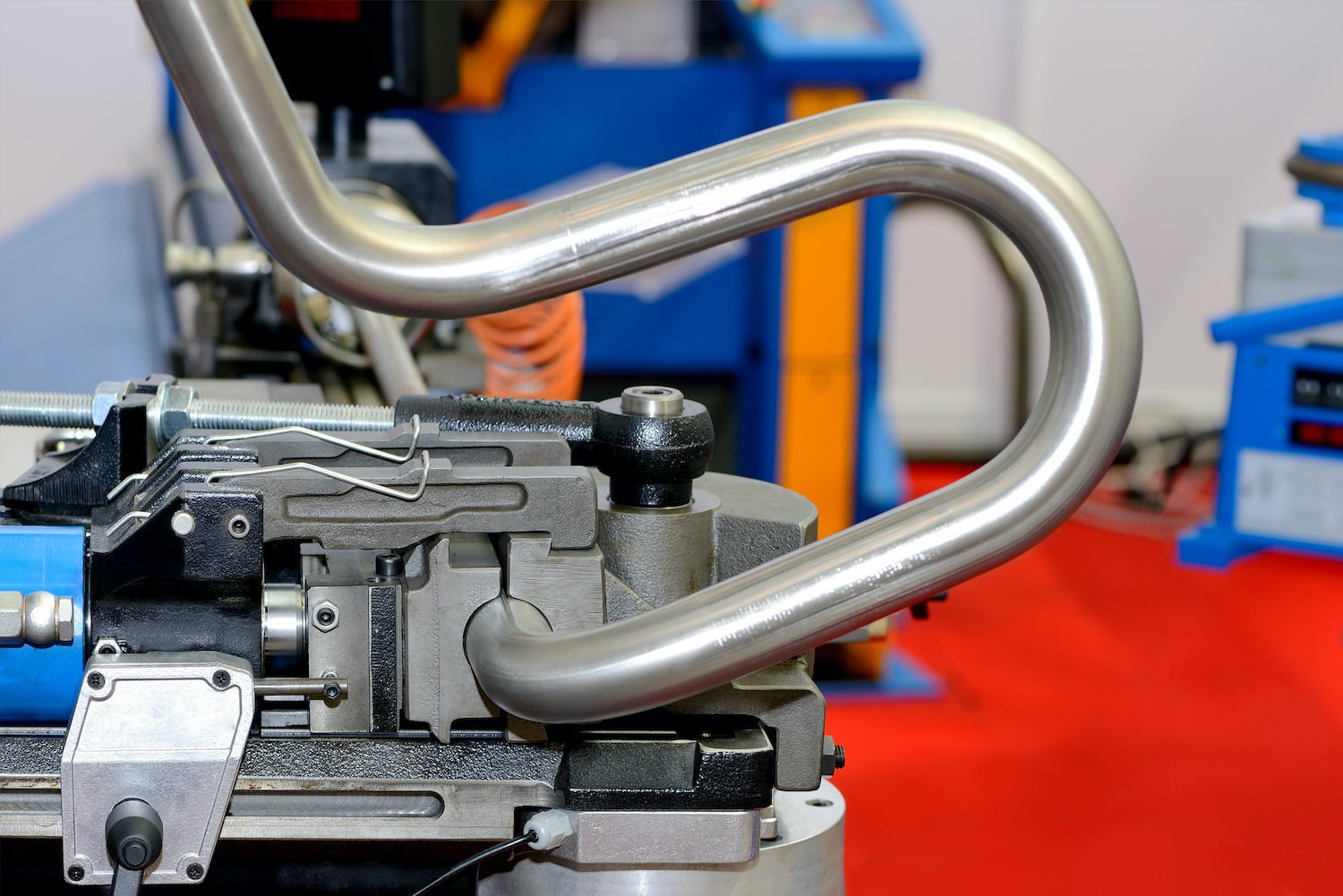

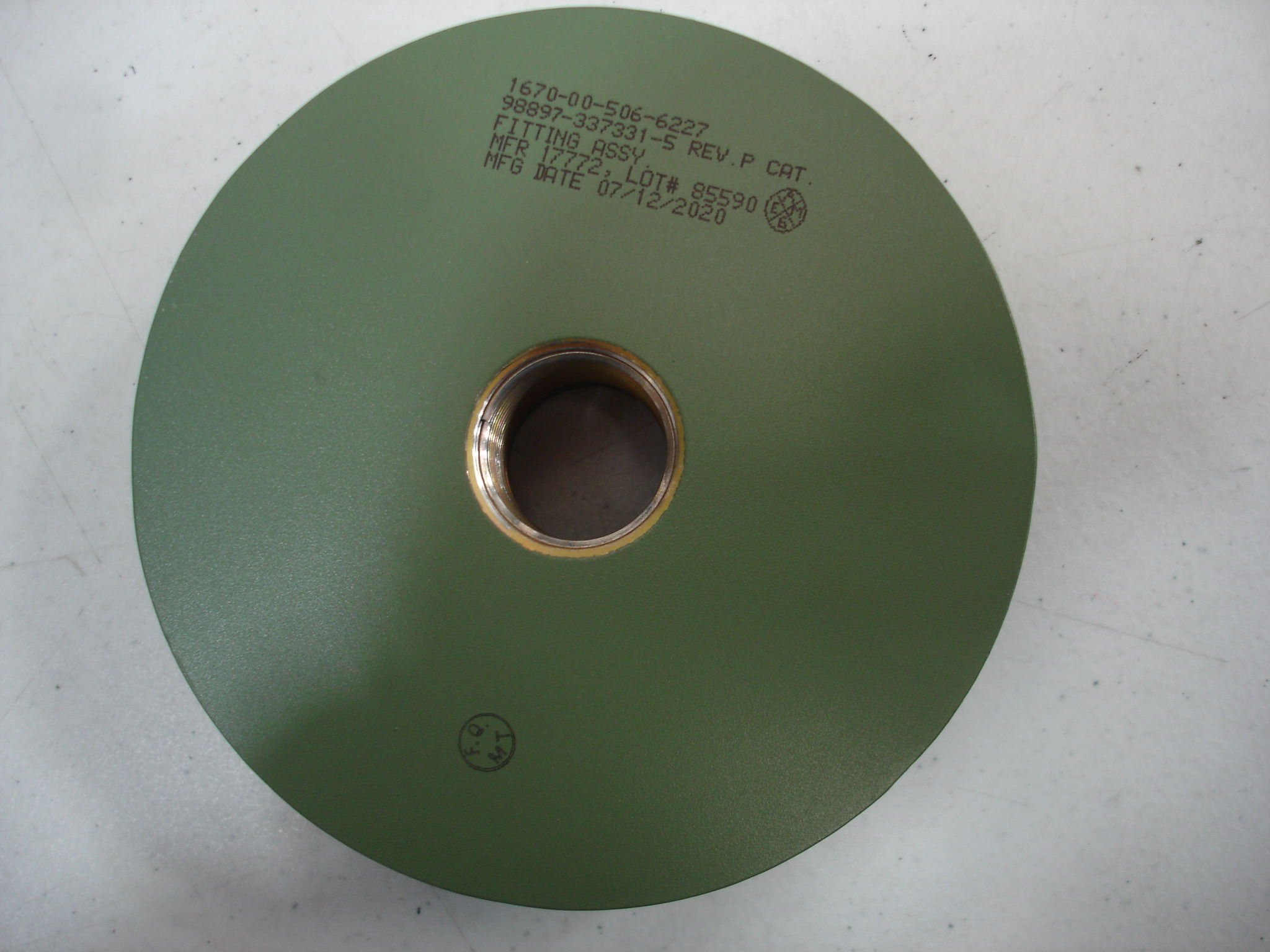

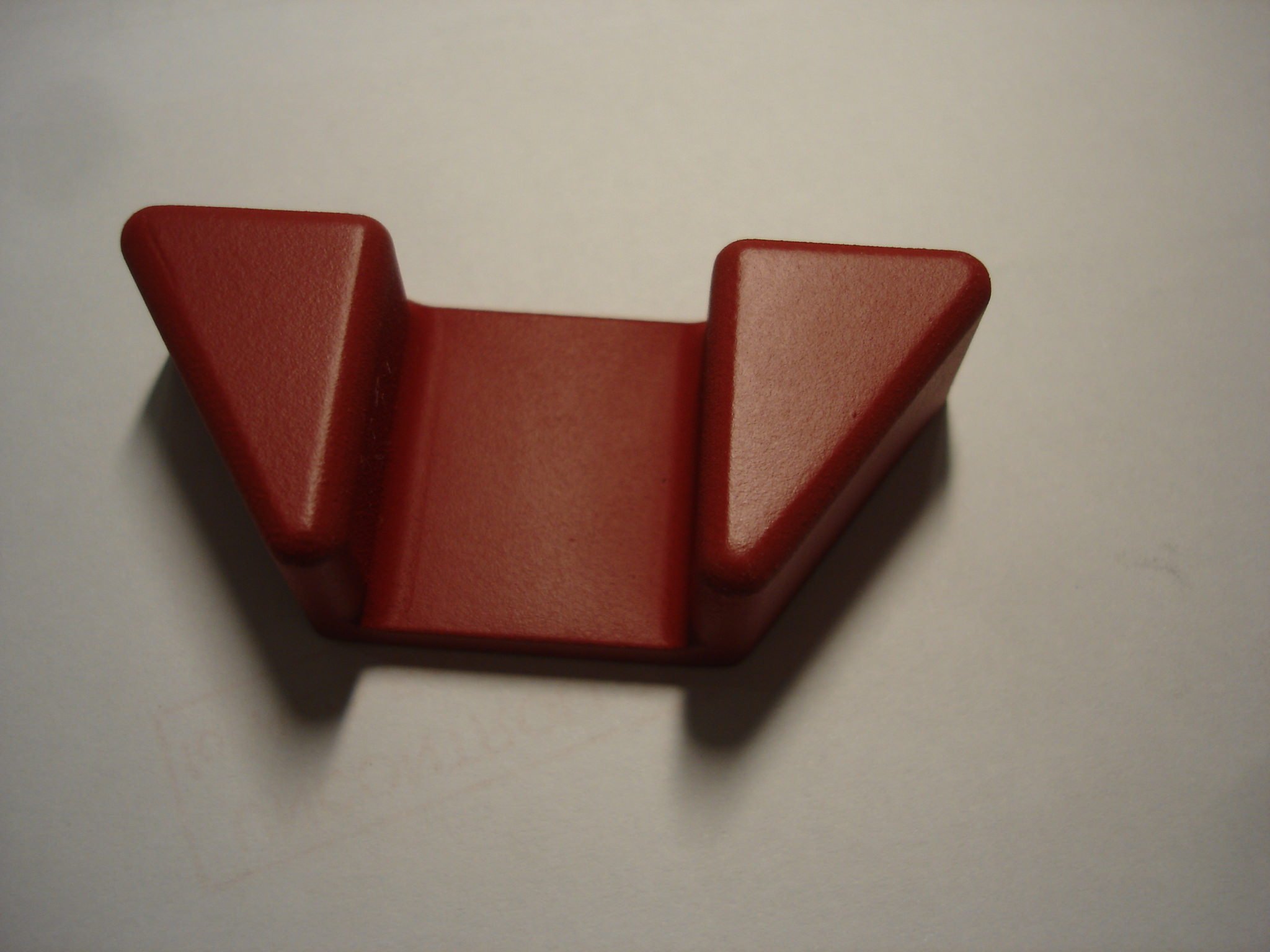

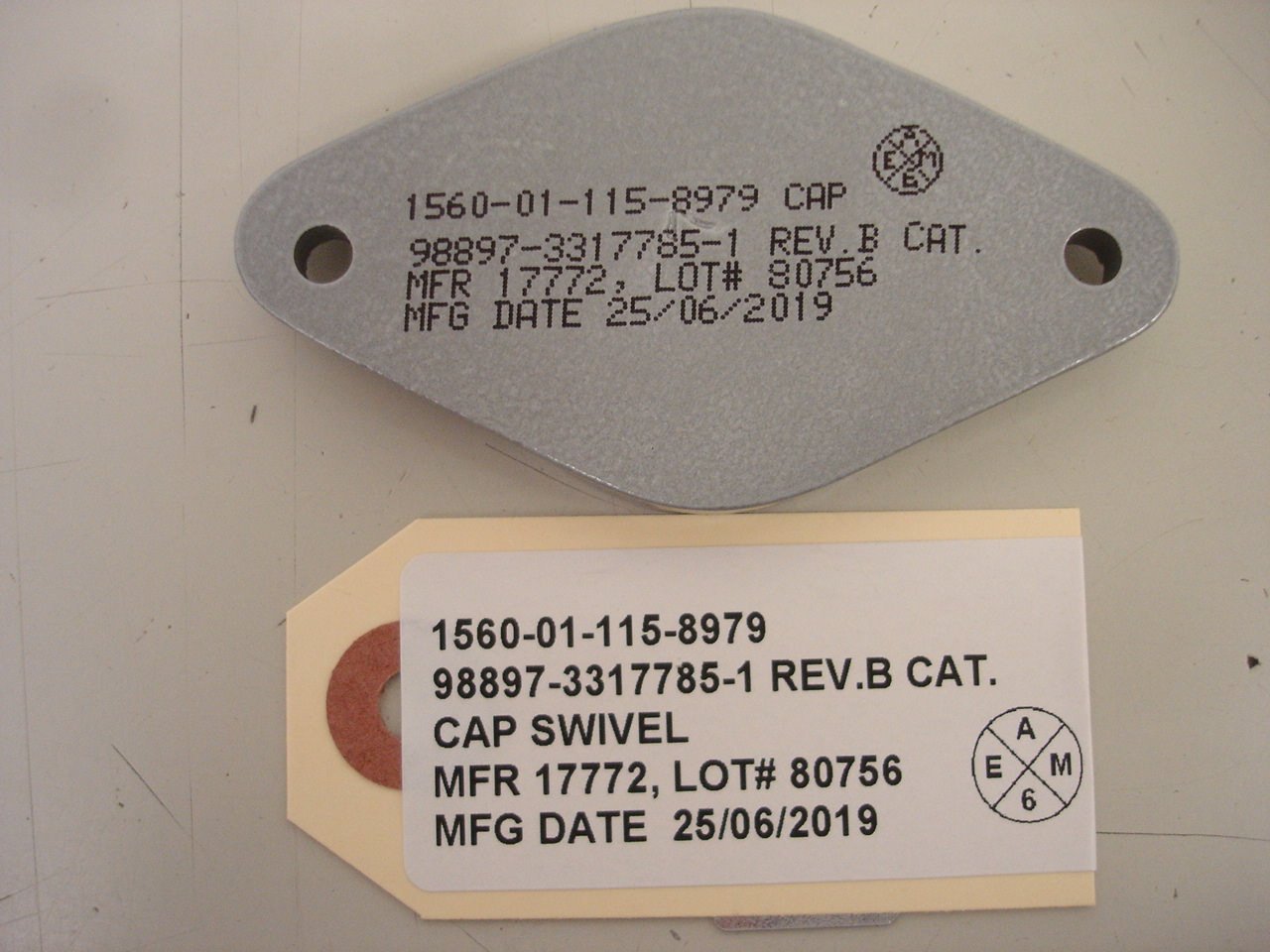

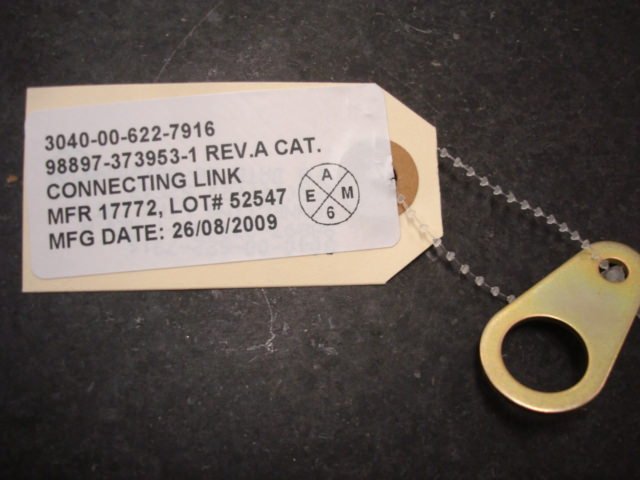

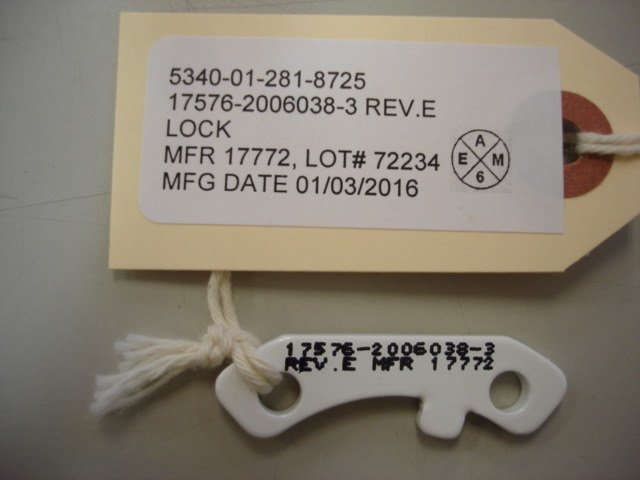

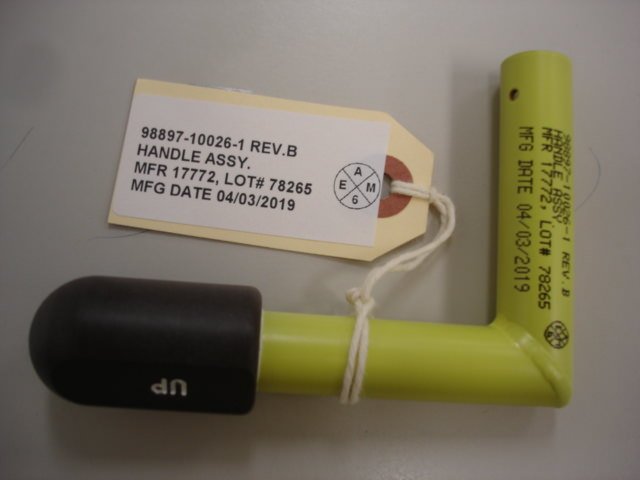

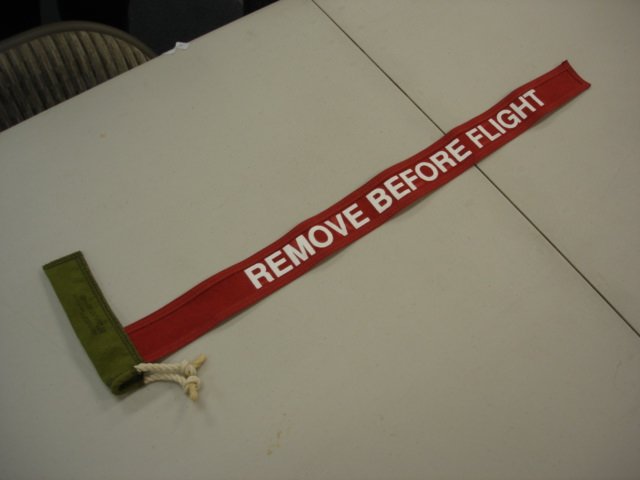

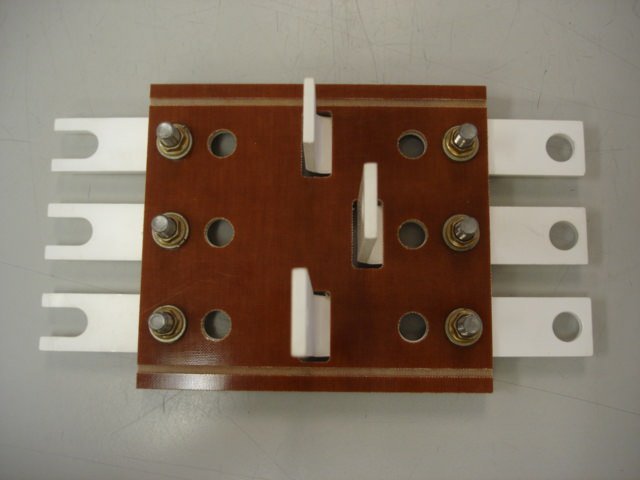

Mechanical Assembly

Complex mechanical assemblies

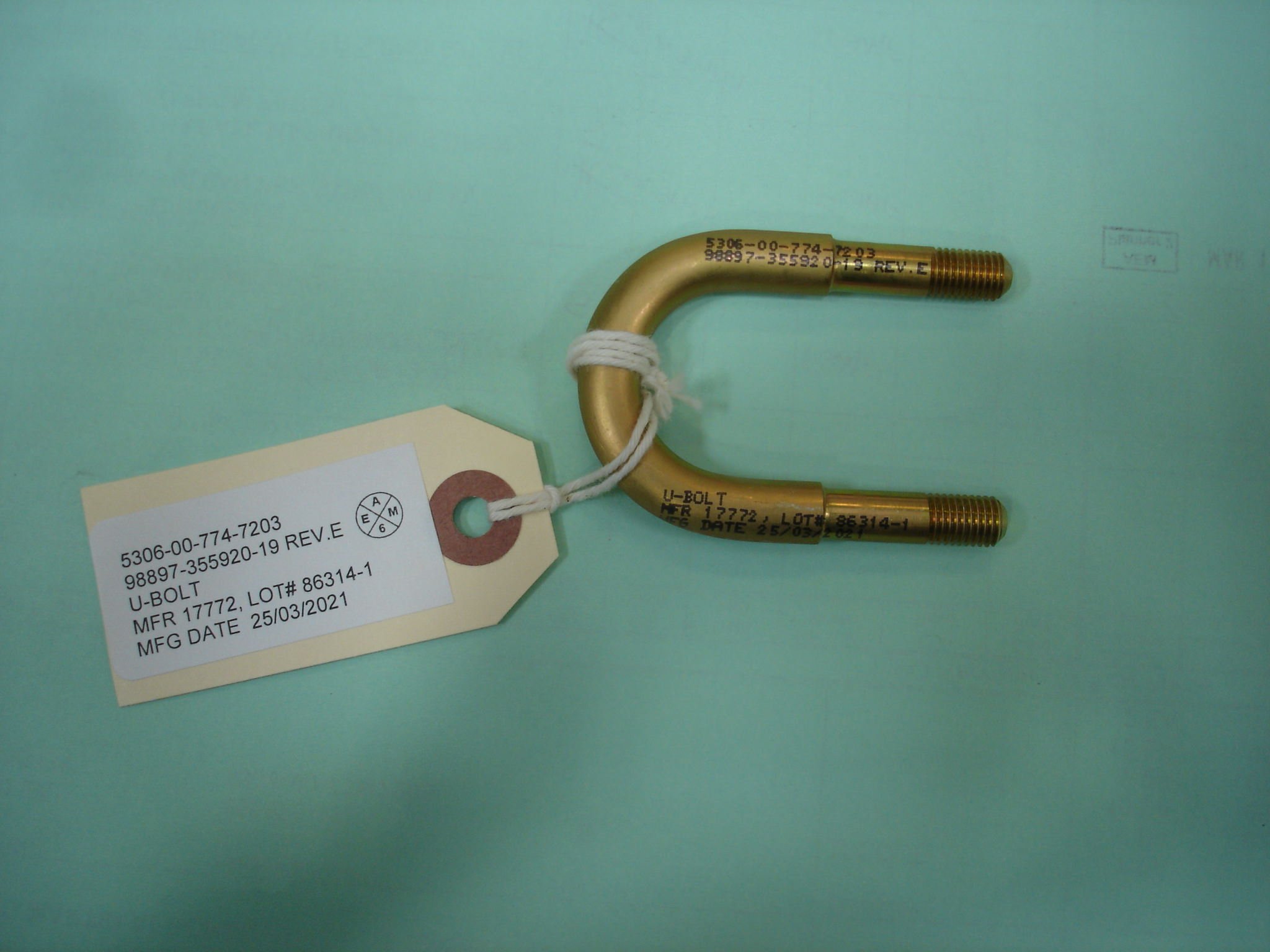

Specialty assemblies (Chain and cable assemblies , Fire seals, Tube assemblies)

Secondary assembly (threaded inserts, riveting, lee plug, bearing installation)